- Joined

- Aug 12, 2013

- Messages

- 858

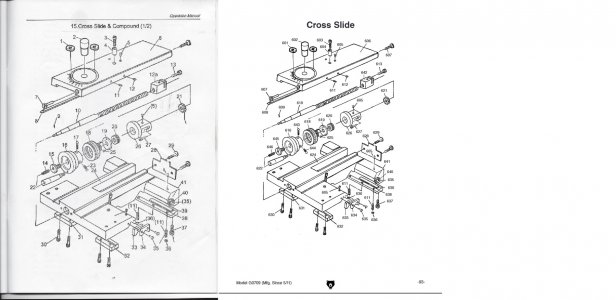

ok, that is just sad.The next picture in the manual says a lot more then what you see here.Don't follow the manual its not even close. The manual calls for parts in the lead screw that don't even exist. part numbers 619 (cover) and 625 (screws) aren't even used

The picture from your manual that you posted is the diagram from the grizzly G0709 manual (the lathe I have)... same picture, same part numbers, everything. Hope there isn't any plagerism going on here.... of parts of manuals for the wrong equipment.

:nono:

...yeah, I know, the same manufacturer probably builds both the 1440E, the G0709G, and the G750G. But Grizzly manuals are written in house in Bellingham, so it seems strange that their illustrations show up in a PM manual.

Look at the grizzly manual for the G0750G. That appears to functionally be the same machine you have... and a quick look at the diagram for the cross slide shows the exact component you have in your pictures (for the non-taper attachment parts)

g0750g_m.pdf

The normal setup (as NOT documented well in your manual) doesn't show how a taper attachment looks. You are trying to attach a taper attachment on your machine, correct?And below is a picture of the taper attachment dial and notice its key way way to large..

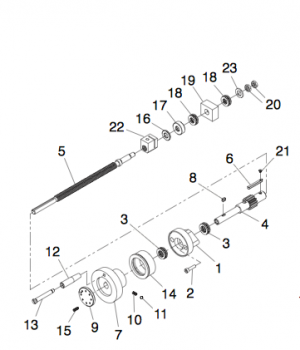

The taper attachment lead screw needs to have a long slot for the keyway, as the lead screw physically shifts under the pull of the taper attachment. I would expect the keys not to be compatible (look at the length of the key PN #6, in the diagram below, it has to be long to maintain engagement as the taper moves the lead screw).

Note: key stock is available everywhere, you can probably run out to the hardware store or local metal supply and buy some and cut your own. No need to wait for fedex.

Here is a good place to look for reference, the product manual for the taper attachment for the Grizzly G0750G. The diagram in it also almost exactly corresponds to the pictures you have shown.

Note that it discusses what you have found out... that the taper attachment hand wheel is different than the normal hand wheel, so this is by design, not sloppiness. This is because it has to incorporate the stub shaft that allows for the lead screw to slide in and out of it, and also that the taper attachment is manufactured to fit on three different lathes, with minor swapping of parts.

http://cdn0.grizzly.com/manuals/t26300_m.pdf

As I have said before, Grizzly does its homework and makes nice manuals... which serve as a nice reference library for people who buy similar equipment elsewhere. They also are a nice source of spare parts, as they warehouse a significant quantity in the US, where smaller importers frequently are unable to get specific parts for months.

I have had one more problem spring up on me as i was walking around the back of the machine i notice this!!! I just hope this isn't going to be a problem child...

Just tap your lathe sharply with a newspaper. It will quickly learn to go outside first.

Not an uncommon problem with this model of lathe (regardless of who is selling it).

Last edited: