- Joined

- May 13, 2019

- Messages

- 1,016

While I'm working on getting my PM-25MV mill converted to CNC, I thought I do some manual machining to help hone my skills.

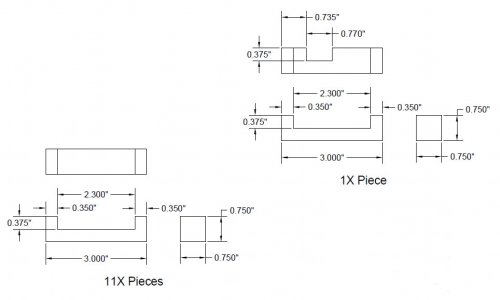

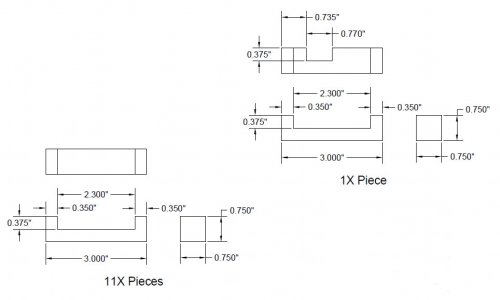

So, I want to make a simple Burr Puzzle. There are 11 pieces exactly the same with a simple cutout. There is 1 piece similar to the others, but with an additional cutout. See drawing below.

So, what would be the best way to do this?

I would like to "gang" cut a bunch of them, but I'm not sure how.

I'm buying 6061 Aluminum 3/4" square stock, so I'm thinking I don't need to mill this dimension. A few thousandths aren't critical. I'm assuming 3/4" stock is +/-0.002"?

My thoughts are:

1. Rough cut to length.

2. Use the mill to make one end square.

3. Mill opposite end precisely to length using a "stop" to make it easier.

4. Setup a "stop" to mill the cutouts all the same.

Is this the proper way to do this? I would like to mill all or most of the cutouts at the same time, but I'm not sure how to do this.

So, I want to make a simple Burr Puzzle. There are 11 pieces exactly the same with a simple cutout. There is 1 piece similar to the others, but with an additional cutout. See drawing below.

So, what would be the best way to do this?

I would like to "gang" cut a bunch of them, but I'm not sure how.

I'm buying 6061 Aluminum 3/4" square stock, so I'm thinking I don't need to mill this dimension. A few thousandths aren't critical. I'm assuming 3/4" stock is +/-0.002"?

My thoughts are:

1. Rough cut to length.

2. Use the mill to make one end square.

3. Mill opposite end precisely to length using a "stop" to make it easier.

4. Setup a "stop" to mill the cutouts all the same.

Is this the proper way to do this? I would like to mill all or most of the cutouts at the same time, but I'm not sure how to do this.