Is there a resource that helps identify what insert you have and gives the cross reference to what insert would work?

This is a little more complicated of a question than you may realize. There are thousands of insert geometries out in the world and many of them only work with one manufacturer's specific tool.

There are a handful of extremely common inserts which you are likely to stick with. These are often available from top manufacturers in the $10-20 per insert range and all the way down to import ones at less than $1 a pop.

Here is a decent webpage to start the discussion:

This homepage offers Mitsubishi Materials cutting tools information.

www.mitsubishicarbide.com

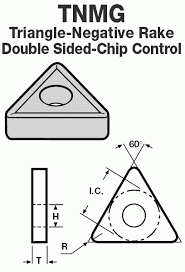

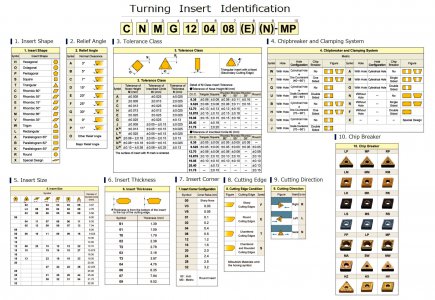

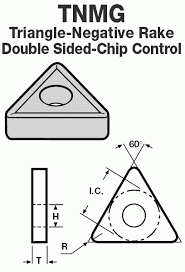

The easy one is the shape. This is the first letter in your insert "TCMT 32.51". T matches up with "triangular". The 60 degree corner angle is good for light machining and finishing but isn't the strongest insert. The larger the corner angle (up to 135 degrees for an octagonal insert) the larger the imparted cutting forces on your machine, but the more robust the insert - these may be good for roughing. The thin "V" inserts (35 degree) can take extremely light and precise finishing cuts with little forces, but will quickly chip if you cut too hard with them.

The second letter is the relief angle. This determines if the tool is positive or negative rake (although negative rake tools with chipbreakers can act like positive rake tools). A positive rake tool like the TCMT 32.51 in the example above will cut with lower cutting forces and horsepower than a neutral or negative rake tool, but it is single sided and less strong. A neutral insert like CNMG432 will be able to flipped over to double the number of cutting edges. Neither my G0704 or my 12x36 lathe have enough rigidity or power to really make good use of negative rake tools with neutral inserts.

The next letter is the tolerance. I don't pay attention to this since I am always re-zeroing my tools, but if you run highly automated production, it might be worth it to you to pay more for an insert which can be replaced and have the tip end up in the exact same location.

The final letter is the clamping system and whether or not it has a chipbreaker. This is selected to match the holder you are using.

The next numbers 32.5 (in the example TCMT 32.51) give the insert size. They are the size in mm of the largest circle that can be inscribed inside the boundary of the insert when looking from the top. Shown as I.C. in the image below.

Some manufacturers will add an extra code here (TCMT32.5^1) to denote the insert thickness, but it is often dropped in lower cost insert designations.

Finally the last number is the insert corner radius. To me, this is the most important number since it determines how the tool cuts. Large radii force you to take large depths of cut, but are strong and want to remove lots of material. Small radii allow you to take whisker thin finishing cuts, but are not strong enough to handle heavy material removal.

Two more somewhat import things to cover are insert grade and coating. The grade is the designation for the actual carbide material. Each manufacturer will have then own, but some are suited to high temperatures, some to highly abrasive materials, some to very hard materials, etc. On top of that, the coating will offer additional protection from heat and wear. Use a coating (even just TIN) on steel, and try to avoid using coatings on aluminum (unless it is specifically made for aluminum).

My commonly used inserts in my home shop are:

- TCMT21.50 (small fine finishing)

- TCMT32.51 (light boring on lathe)

- CCMT32.50 (Finishing in steel)

- CCMT32.51 (Roughing in steel)

- CCGX32.50 (Finishing in aluminum)

- CCGX32.52 (Roughing in aluminum)

- 16ER (External threading)

- 16IR (Internal threading)

- 11IR (Internal threading for small holes)

There is a lot more to indexable tools, but this is a starting place. I strongly suggest buying indexable tools with the required insert and hardware marked on the tool. Shars does this with all of their tools as well as most big name manufacturers.