- Joined

- Feb 1, 2015

- Messages

- 9,575

I recently had the main circuit breaker trip on my 100 amp sub panel. None of the individual breakers had tripped so I reset the breaker and we continued preparing for a houseful of party guests that we were expecting in a few hours. The breaker tripped twice more that afternoon and I figured that it was either the perfect storm where the central A/C, the well, and the electric hot water heater were plus a few other appliances chose to come on at the same time or I had a failing breaker.

The next day, I pulled the cover on the panel and put my clamp-on ammeter on the feed wire. The central A/C was running at 20 amps and when the well kicked in the load increased to around 30 amps. The highest current that I saw was 40 amps. Same on the other leg. I left the meter in place to monitor current and turned my attention to other matters with the intention to pick up a new breaker on the next trip into town.

A day later, the breaker tripped again, The current was around 40 amps again and I think I solved the mystery of the tripping breaker. The breaker was quite warm to the touch, as was the feed wire. Then I remembered about aluminum cold flow. Sure enough, the clamping screw were not tight. I tightened them and the breaker temperature is now close ambient and it hasn't tripped again.

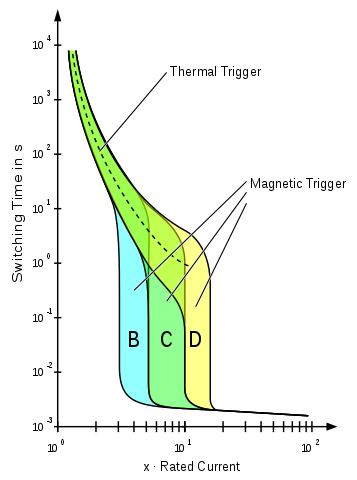

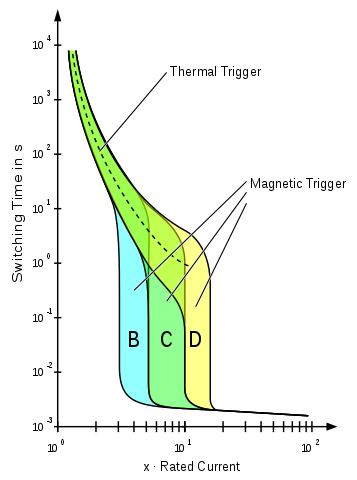

In addition to the magnetic portion of the breaker tripping from a dead short condition, there is also thermal breaker. The heat generated by by the load current will trip the breaker with time inversely proportional to the average current draw as shown below. Adding heat to the breaker by virtue of a high resistance connection will shift the curves to the left, causing the breaker to trip when in normal operating range.

I recall some thirty or forty years ago, there was a push to switch to aluminum wire for residential use because of lower cost. It was short lived due to a number of electrical fires caused by cold flow. Aluminum wiring was subsequently disallowed by code, at least in Wisconsin, and most electrical components carry a "not for aluminum wire" warning. However, it still remains used for feed wire.

The sub panel was rewired about 17 years ago. When the wiring was done, the wires were liberally coated with antioxidant paste and tightened securely at the time. Given that the connections were loose in this panel, I will be checking the other three panels on the property where aluminum wire feeds in.

The next day, I pulled the cover on the panel and put my clamp-on ammeter on the feed wire. The central A/C was running at 20 amps and when the well kicked in the load increased to around 30 amps. The highest current that I saw was 40 amps. Same on the other leg. I left the meter in place to monitor current and turned my attention to other matters with the intention to pick up a new breaker on the next trip into town.

A day later, the breaker tripped again, The current was around 40 amps again and I think I solved the mystery of the tripping breaker. The breaker was quite warm to the touch, as was the feed wire. Then I remembered about aluminum cold flow. Sure enough, the clamping screw were not tight. I tightened them and the breaker temperature is now close ambient and it hasn't tripped again.

In addition to the magnetic portion of the breaker tripping from a dead short condition, there is also thermal breaker. The heat generated by by the load current will trip the breaker with time inversely proportional to the average current draw as shown below. Adding heat to the breaker by virtue of a high resistance connection will shift the curves to the left, causing the breaker to trip when in normal operating range.

I recall some thirty or forty years ago, there was a push to switch to aluminum wire for residential use because of lower cost. It was short lived due to a number of electrical fires caused by cold flow. Aluminum wiring was subsequently disallowed by code, at least in Wisconsin, and most electrical components carry a "not for aluminum wire" warning. However, it still remains used for feed wire.

The sub panel was rewired about 17 years ago. When the wiring was done, the wires were liberally coated with antioxidant paste and tightened securely at the time. Given that the connections were loose in this panel, I will be checking the other three panels on the property where aluminum wire feeds in.