I used one of these on my Kubota.I bored a Love joy and used the Fenner to connect it to the 22mm shaft coming off the crank.Was able to find the needed size on ebay for $20. shipped.This is what I found when searching Fenner Drives that looks like it would be applicable to my motor shaft.

They are a bit costy, at about $70.

View attachment 99790

http://www.fennerdrives.com/trantorque/_/Trantorque-OE-17mm/?s=ZnwyMzE4Oml8MTAyNA==

- Series: Trantorque OE

- Component Bore Diameter: 32 mm

- Shaft Diameter: 17 mm

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pully On A Treadmill Motor Shaft?

- Thread starter Franko

- Start date

A cone clamp will do, great for fixing on to plains shafts.

http://www.ringfeder.com/en/international/products/ringfeder/?g=382

http://www.ringfeder.com/en/international/products/ringfeder/?g=382

Franko, I have a spare 1/2 x 13 LH tap if you need one. I bought a batch(new old stock) on E-Bay a while back. I've made a couple adapters for treadmill motors with them. All the DC PM treadmill motors I've collected have that thread on them. I made the pulley for the TM motor that runs my mill from the small end of it's flywheel.

Chuck

Chuck

- Joined

- May 3, 2016

- Messages

- 5

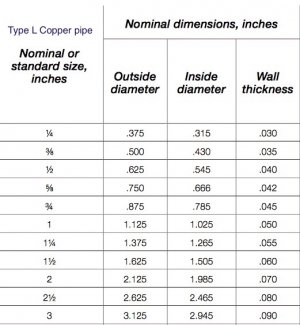

I am new to hobby machinist, but I do have a tip here. In addition to the left hand 1/2 x 13 thread on tread mill motors, the pully issue is easily solved. Type L tempered copper has an almost perfect ID to fit the 17mm shaft ( usually less than .03 mm ie: an slight interference fit) While the OD is within +/-.001 of a 3/4" pully bore (makes an excellent no play bushing). I have used this trick many times in the past, and I will try to post pictures later.

Also I have successfully used multiple flats ground into the OD of the 17mm shaft and a machined Steel pulley with multiple set screws, even adding a third set screw (offset 60deg.).

Also I have successfully used multiple flats ground into the OD of the 17mm shaft and a machined Steel pulley with multiple set screws, even adding a third set screw (offset 60deg.).

Last edited:

- Joined

- Feb 17, 2013

- Messages

- 4,406

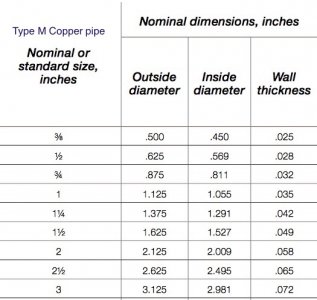

OK, I'm a bit lost here. I assume you're talking about pipe, not fittings.I am new to hobby machinist, but I do have a tip here. In addition to the left hand 1/2 x 13 thread on tread mill motors, the pully issue is easily solved. Type M tempered copper has an almost perfect ID to fit the 17mm shaft ( usually less than .03 mm ie: an slight interference fit) While the OD is within =/-.001 of a 3/4" pully bore (makes an excellent no play bussing). I have used this trick many times in the past, and I will try to post pictures later.

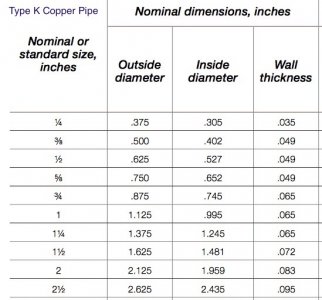

Went to http://www.copper.org/publications/pub_list/pdf/copper_tube_handbook.pdf and looked up pipe dimensions (Pages 62 thru 64 for K, L, and M). Parts of the tables for K, L, and M (with my labels) are reproduced below.

Nothing in the M table looks like it has and OD of ¾". However, both K and L pipes of nominal ⅝" size have ODs of .750". Of the two, it looks like L's ID of .666" is a better fit to 17mm (.669") than K's ID of .652". Am I missing or mis-reading something here?

Your tip is very useful, but I just want to be sure I get it right.

- Joined

- May 3, 2016

- Messages

- 5

Sorry, thanks for catching that it is Type L rigid but in 5/8 as the wall is nominal .042 though it seems to run closer to .0405 to .041 I have a piece in front of me that I just cut a bushing from and the ID Mich's at .669 and is a no slop slight interference fit for my motor shaft that I have on the bench, and the OD comes in at .751 (now where is my roll of 120 grit). Type M does not even come in 5/8 ID. As an added note Grainger down here stocks it in 2 foot lengths for $5.84 including tax. None of the big box stores seem to carry 5/8.

I edited my previous post to eliminate confusion.

I edited my previous post to eliminate confusion.