- Joined

- Sep 13, 2013

- Messages

- 276

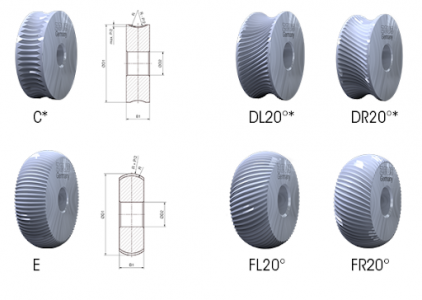

Putting some grip (stippling) on an aluminium drive pulley.

I've always wanted to work out a way to put some extra grip on a home made drive pulley to prevent or cut down on belt slippage. It would be nice to have the tooling that Wilesco use on their grooved pulleys. I had a Dremel saw accessory that the outer plastic shell broke and I thought what can I do with the saw blade. Rudimentary, but it worked well. I should be able to work out now a way to mount it so it doesn't need to be held, though its not as dangerous as that looks and being hand held allowed me to skew the saw blade at the various angles needed easily.

I've always wanted to work out a way to put some extra grip on a home made drive pulley to prevent or cut down on belt slippage. It would be nice to have the tooling that Wilesco use on their grooved pulleys. I had a Dremel saw accessory that the outer plastic shell broke and I thought what can I do with the saw blade. Rudimentary, but it worked well. I should be able to work out now a way to mount it so it doesn't need to be held, though its not as dangerous as that looks and being hand held allowed me to skew the saw blade at the various angles needed easily.