- Joined

- Mar 26, 2018

- Messages

- 2,724

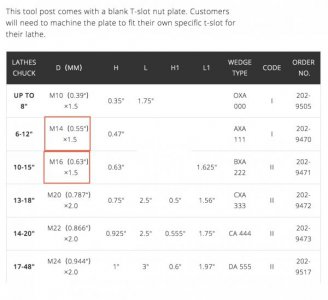

I run a Enco 12x36 with an AXA sized wedge toolpost. Toolholders up to 5/8" are available. I can stall my 1.5 HP motor long before I have problems with the rigidity of the toolpost. I've been happy with it. Nothing wrong with the BXA either, but less adjustment room. You will do great with either.