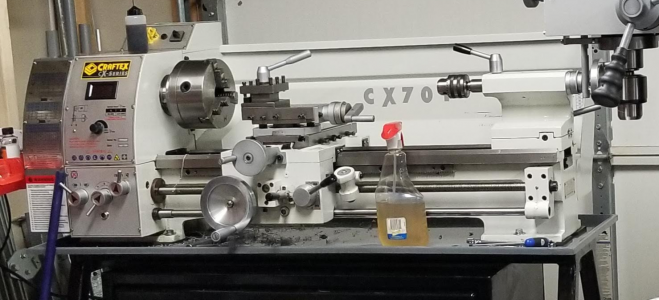

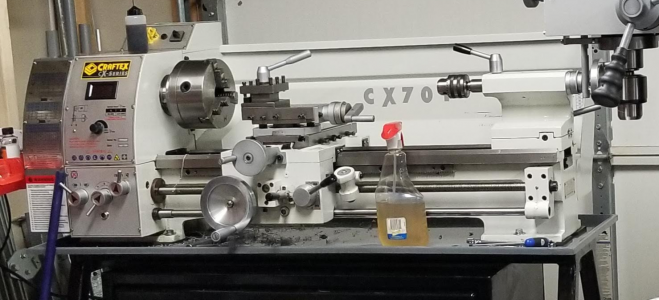

Well I sold my brand new 10x22 lathe the other day after less than 30 days in my shop. My first project on it was the QCTP mount. Anyhow onto lathe #2 well actually #3 as #1 was a 7x12.

I picked up a 12x28 (really probably an 11x27) just before selling my 10x22. This time I bought the wedge AXA QCTP. Last time I did this https://www.hobby-machinist.com/threads/quick-change-tool-post-for-10x22-busybee-cx706-done.81966/

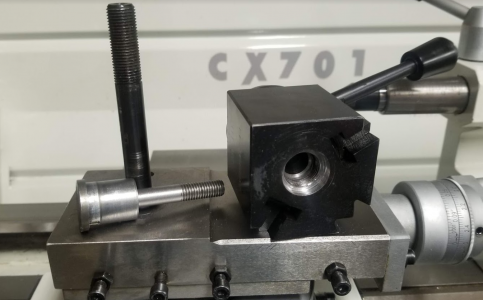

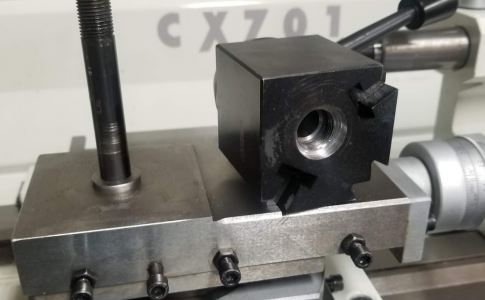

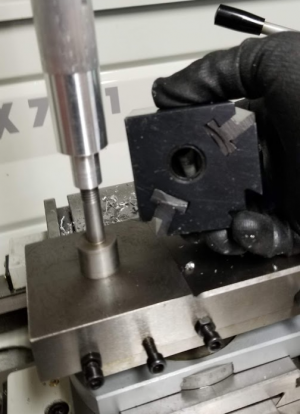

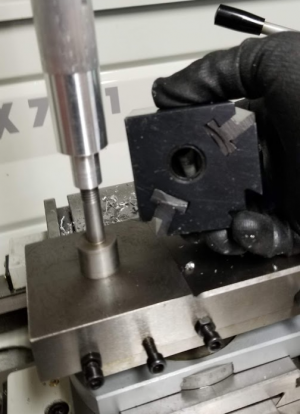

This time I think I want to keep the ability to use the 4 tool stock holder. The plan is to bore out the bottom of the AXA QCTP to fit the stud on the cross slide. Only a slight amount of widening will be required. Then I want to turn a threaded adapter nut column (4140) that will fit down into the tool post and tighten it into the stock 10mm bolt. The stock 10mm stud does not go past the top of the tool holder. I have seen other people use this approach before. There will only be 0.2" of material diameter left on the adapter to mount to the 10mm stud (see pic with 0.1" radius). There will be a fairly long engagement of thread though to hold it in place. Anyone have a better idea?

I picked up a 12x28 (really probably an 11x27) just before selling my 10x22. This time I bought the wedge AXA QCTP. Last time I did this https://www.hobby-machinist.com/threads/quick-change-tool-post-for-10x22-busybee-cx706-done.81966/

This time I think I want to keep the ability to use the 4 tool stock holder. The plan is to bore out the bottom of the AXA QCTP to fit the stud on the cross slide. Only a slight amount of widening will be required. Then I want to turn a threaded adapter nut column (4140) that will fit down into the tool post and tighten it into the stock 10mm bolt. The stock 10mm stud does not go past the top of the tool holder. I have seen other people use this approach before. There will only be 0.2" of material diameter left on the adapter to mount to the 10mm stud (see pic with 0.1" radius). There will be a fairly long engagement of thread though to hold it in place. Anyone have a better idea?

Last edited: