-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Quarantine Projects!

- Thread starter Weldo

- Start date

- Joined

- Oct 16, 2019

- Messages

- 6,570

Just say no to grease! It attracts and worse, retains chips which can lead to premature wear. I use 75wt gear lube on my SB. Seems to be fine. And I have several quarts of it due to my moto having a shaft drive.Did a little lathe maintenance today as well.

I've been unhappy with the gear mesh for the power feeds on my old Atlas. The selector has an adjustable plate such that when I adjust it to a good mesh for the left carriage feed the right carriage feed just barely meshes at all. This has led me to rarely use the "right traveling" power feed. This isn't really a big deal but unfortunately the right carriage feed is also the cross slide "in" feed so I rarely used that either.

What I had to do was make a new plate with new holes so that I had good mesh in both settings. The old plate is on the bottom

and my newly made one is on top. Mine has no adjustment possible but since I drilled the holes to allow for good mesh I don't think it will matter.

View attachment 318973

Here's the old one mounted. The screws are not in but you get the idea. Notice on the above pic how my new holes are spread farther apart from center. I'm guessing this is because of wear in the gears. I'm sure when it was new the old plate was just fine.

View attachment 318972

I couldn't really get a good pic of the gear mesh but the way I set them both was to bottom out the teeth using the selector then back off a bit so they had some little bit of backlash.

It seem to run well. All the feeds work and now I can use all the feeds without worrying about gears slipping or striping out.

What do you guys like for lubing gears? I heard automotive gear lube is good, the 90W to 140W variety. I didn't have any so I smeared some heavy grease on 'em.

- Joined

- Sep 27, 2014

- Messages

- 3,123

A while back someone gave me this mag drill with a dead mag , doing a little cleaning I found a electromagnet that was a little bigger magnet than the original. Called the manufacturer and it is a 300 watt with a 2000 lb breakaway, made a 1/2” adapter plate mounted it to the drill , turned it on on the welding table and it moved the table around without the mag moving at all , it’s a heavy table. Popped a 1 1/2” hole in some 1/2” plate like it was butter. Things a beast. The pics

Are the old mag, the new one is 2” wider and 3” longer , I think it’ll work out.

Are the old mag, the new one is 2” wider and 3” longer , I think it’ll work out.

- Joined

- Sep 7, 2019

- Messages

- 674

Nice drill! I used to work for a weldshop that had an old Milwaukee mag drill, boy did it come in handy. I dare say that you can do things with it that might be impossible otherwise. Cutting an 1-1/2" hole in 1/2" plate with a hand drill and hole saw would probably take twice as long and require ten times the effort. Not to mention the safety issue. Many a guy has gotten a tweaked wrist from a 1/2" electric hand drill. And broken bits too!

Good score!

Good score!

- Joined

- Feb 9, 2017

- Messages

- 5,231

I live for fixing and using old tools. Not a restoration guy because once I get in the weeds trying to restore I usually lose steam and it becomes a basket case. One of my better hand tool fixes was somebody gave my FIL an old Rockwell hand held bandsaw with a broken blade guide rest. It was my first project on a mill at the place I was working at. Still have the old bandsaw and it's not something I use everyday but when I need it, it's saved the day too many times.

- Joined

- Sep 7, 2019

- Messages

- 674

That drill is bonkers! Definitely a nice tool. And the holder is beautiful! How'd you get such a fine finish?

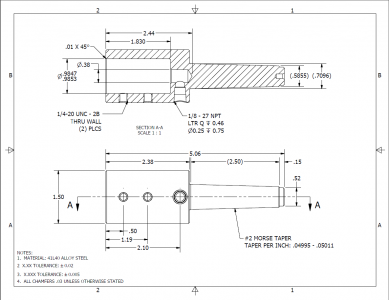

I even like the drawing! I've been delving into CAD learning lately, what program did you use for that drawing? It looks great!

I even like the drawing! I've been delving into CAD learning lately, what program did you use for that drawing? It looks great!

- Joined

- Sep 7, 2019

- Messages

- 674

I live for fixing and using old tools.

Cleaning up and fixing old tools is pretty cool. I spent a few months restoring my lathe years ago. Did an old Whitney No.38 bench shear that came out nicely. I've been eyeing up a manual notcher too lately. Something like this would be cool to have.

I really like the old manual metalworking machines.