- Joined

- Sep 2, 2013

- Messages

- 5,090

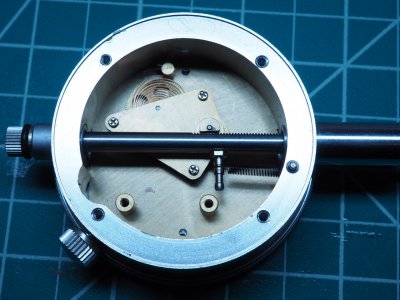

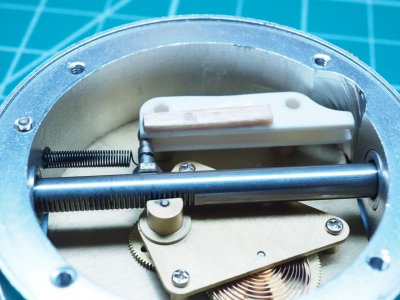

Back on the mower rehab. There is a gear toothed lever that engages an external shaft mounted gear on each of the hydro-static drive units that are engaged by pushing the right hand steering lever outward which acts as a brake for both drive units. The teeth on the levers had been almost completely worn away due to improperly installed linkage, and not having a return spring incorporated in the original linkage design. I looked up the part on line and they wanted $63 plus shipping for each one. $150 for two little pieces of pot metal. So another self inflicted job. Decided to build up the worn tooth area with JB Weld, and try my hand at free form tooth creation. Seems to have worked pretty well, but time will tell. May end up remaking them out of steel if these don't hold up. The floor board area originally had three sections of non-skid material glued on, but only one remained, so I sanded those areas down and applied several coats of rubberized rattle can undercoating. Looks decent, and seems pretty tough. Mike