Dang! You guys have all been working on big projects. I feel like I'm just piddling.

Bought one of the $12 misters off of Ebay, and printed a couple of mounts for it.

Didn't really like that one, just seems too big on my little mill, but I'll have it if I ever need it. Second version has four rare earth magnets pressed into the base....

Not terribly impressed with the mister, but it will do. You have to keep the bottle within about a foot of the same height as the nozzle. Too low, and it won't draw, too high and it dribbles even without air.

I have a set of small drivers for RC, and the ratchet handle gave up the ghost last year, so I'm printing dedicated handles for each.

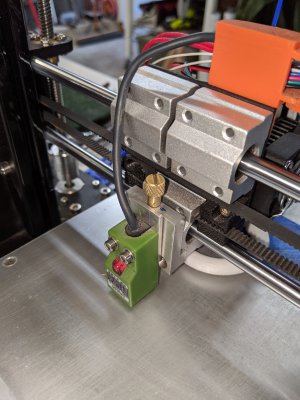

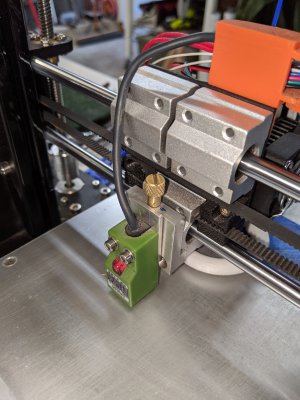

My printer has a bed sensor for adjusting the nozzle height. Originally the height of the sensor was just hit or miss, tightening up two cap screws, making adjustments tedious as f***. A couple of years ago I machined an aluminum slide mount for it which used a M4 button head screw to set the height. This was light years better, but still a pain having to grab a hex driver every time I needed to dial in the height. These adjustments are often 1/8 turn to fine tune things, so still fiddly. I took a leap and turned a brass M4 x 44mm thumb screw to do the job, and surprised myself by nailing it the first time. Much better...

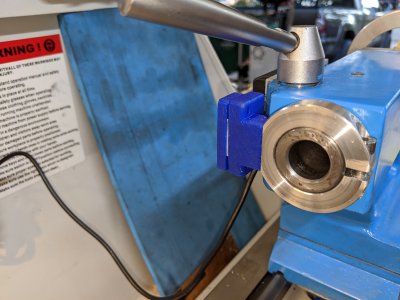

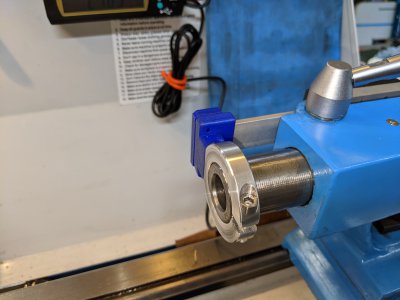

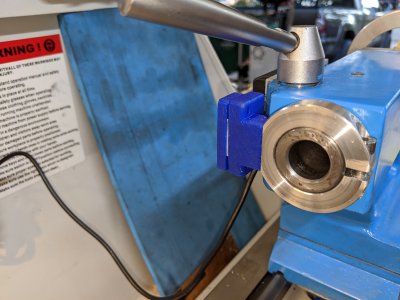

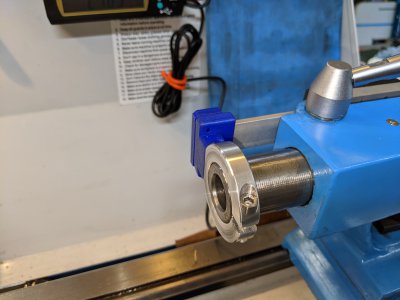

So dummy me had to replace one of the Igaging scales on the mill, and bought one that was too short, and had to buy another one the correct length. Not sure where, but I saw where someone had put a DRO on the tailstock quill of a lathe. Since I already had an extra scale, why not? Made a split collar for the quill (narrow enough so that I can still eject the Morse taper tools) and printed the scale mounts.

Jury is still out, not a fan of the location of the display, but it works pretty good, and if it is ever in the way, it's just two screws to pop it off.

Finally, just for fun a new adult size speed knob for the lathe.

And a couple of adult size, not sloppy-ass plastic crank handles for the mill.

Hope everyone is staying safe and sane, particularly you @Weldo it's crazy out in the world these days.

Bought one of the $12 misters off of Ebay, and printed a couple of mounts for it.

Didn't really like that one, just seems too big on my little mill, but I'll have it if I ever need it. Second version has four rare earth magnets pressed into the base....

Not terribly impressed with the mister, but it will do. You have to keep the bottle within about a foot of the same height as the nozzle. Too low, and it won't draw, too high and it dribbles even without air.

I have a set of small drivers for RC, and the ratchet handle gave up the ghost last year, so I'm printing dedicated handles for each.

My printer has a bed sensor for adjusting the nozzle height. Originally the height of the sensor was just hit or miss, tightening up two cap screws, making adjustments tedious as f***. A couple of years ago I machined an aluminum slide mount for it which used a M4 button head screw to set the height. This was light years better, but still a pain having to grab a hex driver every time I needed to dial in the height. These adjustments are often 1/8 turn to fine tune things, so still fiddly. I took a leap and turned a brass M4 x 44mm thumb screw to do the job, and surprised myself by nailing it the first time. Much better...

So dummy me had to replace one of the Igaging scales on the mill, and bought one that was too short, and had to buy another one the correct length. Not sure where, but I saw where someone had put a DRO on the tailstock quill of a lathe. Since I already had an extra scale, why not? Made a split collar for the quill (narrow enough so that I can still eject the Morse taper tools) and printed the scale mounts.

Jury is still out, not a fan of the location of the display, but it works pretty good, and if it is ever in the way, it's just two screws to pop it off.

Finally, just for fun a new adult size speed knob for the lathe.

And a couple of adult size, not sloppy-ass plastic crank handles for the mill.

Hope everyone is staying safe and sane, particularly you @Weldo it's crazy out in the world these days.