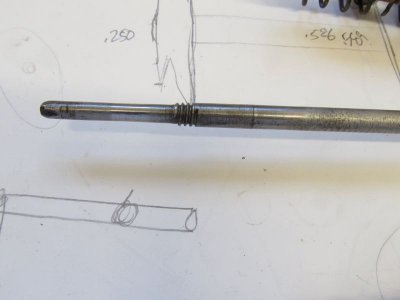

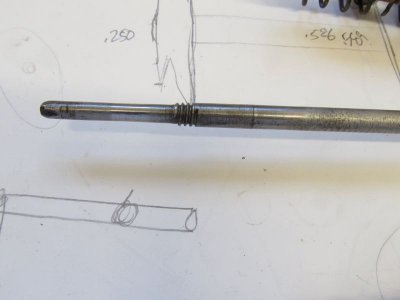

This is a mandrel from a vintage spinning wheel. I have replicated a number of these using taps and dies but would like to actually know how the originals were done. My guess is on a manual lathe of some sort as it appears the cutting action on this left hand thread starts from a dead stop.

Any ideas or thoughts?

Any ideas or thoughts?