- Joined

- Oct 6, 2010

- Messages

- 699

I think the ball detent clutches are only meant to activate in the event of a crash , e.g. the tool post and chuck start to jam together.

I find i start getting a little tense if doing a 100th DOC …………………..

You have a seperate feed and threading bar so the problem of it kicking in during threading won't be an issue …………………….

Bob mentioned the shear pin protective devices, I had one on an old lathe that had been replaced with a roll pin, thats very very bad …………………………………….

You could try jamming the lathe with somthing soft like wood and hand turning the chuck to test it's function.

Stuart

Stuart,

Thanks for you input.

1. You first point is a good one and I think that the previous operator/s have jammed it way too many times. The gear that meshes with the worm gear that slides on the feed rod was missing when I got the lathe. There was a new gear in the tool box but the shaft it mount on is damaged and needs replacement.

2. What size and brand lathe did you take the 100th DOC on I would really like to learn what is a reasonable DOC would be for my lathe?

3. I agree, having separate lead screw and feed rod is a good thing!

4. You are very correct, roll pin do not act as shear pin very well.

5. I am thinking along that line of a static jam and check. Maybe I can rig a lever on the feed rod and use a spring scale to see what torque it takes to strip the ball detent clutch. I am also thinking of doing the same on the (factory set) parts machine before I take it apart for parts. I don’t know yet if there is any rust damage in the sleeve bearing at the tailstock end. The machine was stored in a three sided building for an unknown period of time. I will have to make sure that all the parts are cleaned and lubricated first.

John,Benny -

I have an older Grizzly 12x24 lathe. The feed lever on the carriage lets you select either lengthwise feed (up) or cross feed (down). Center is neutral. I'd not had it very long, and was doing a lengthwise cut toward the chuck. Got to the stopping point and accidentally lowered the feed lever too far, crashing the tool into the side of the work. I gotta admit I had things running a bit fast at the time.

Loud noises, of course, before I hit the e-stop. I assumed I'd eaten a gear in the saddle. In the process of dismantling it dismounting it, I saw the feed drive rod come apart. Lo and behold - the very ball detent clutch you first posted about! Did some thorough checking, and nothing was broken or bent.

I did adjustment the clutch any when I reassembled it, and have no idea where the PO had set it. But I've never had any problems with the feeds, and the clutch did its thing when it was needed. I'd surmise that the setting is not critical. There's probably a huge difference in torque on the rod between even heavy machining and a tool crash.

PS - I've since added a swing-away stop that prevents lowering the feed select lever too far when disengaging from lengthwise feed.

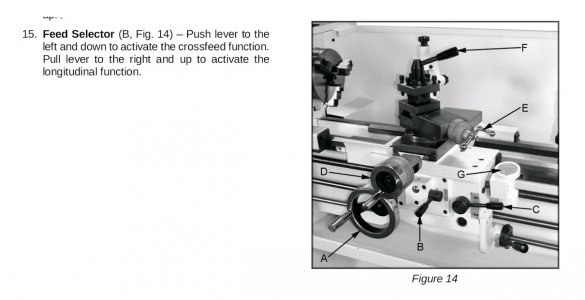

You raised a good point about the feed lever and learning to use it safely. I have not had a chance to operate my lathe so I looked at the manual again and went into the shop and looked at the lathe again. What I have is similar to the manual illustration below.

There is a pin in the lever that rides in a slot milled behind it to prevent what happed to you. The slot consist of a horizontal central portion with a vertical and downward slot at each end. It looks idiot proof to me so I should be okay. The parts machine I have works very smooth but the project machine does not. There is some kind of damage that will have to be corrected. I have the apron off the machine but have not taken it apart yet. Too cold in the shop!

Benny

The Orphanage Never Closes