Hi All!

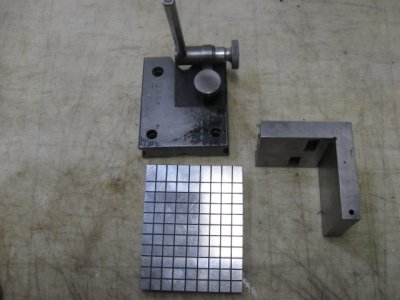

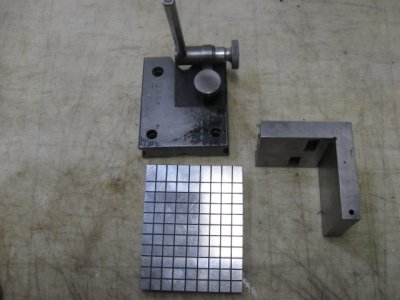

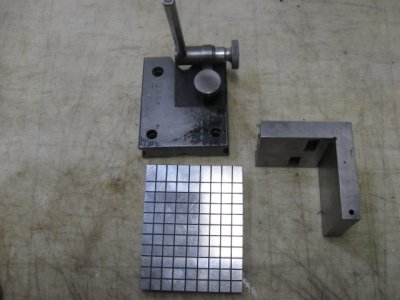

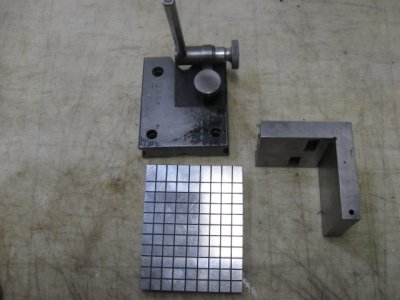

I've got a few questions about a surface gage & an angle plate that I recently purchased that I'd like to present here. I have attached 3 photos that should describe the instruments far better than my words can.

The main question that I have about the surface gage concerns the removable base. I'm wondering why this base was added, what it is called and what purpose of the cross hatching on the bottom of it serves. It is attached to the surface gage's base via 3 socket head set screws.

The other question about the base regards its dimensions. The base measures 3.384" wide & 4.000" front-to-rear. It's 1.082" thick (without the added base, which is 0.534" thick.) What would such a large surface gage be used for? I also wonder why the spindle is so short, at 5.178" (0.375" diameter).

In most other respects, it looks 'normal'. There is a vee groove in the bottom, there's a tilt screw & a spindle clamp. There are no hang pins nor is there a

scribe or it's holding clamp.

I can not find this size gage in any of my catalogs, nor can I find one with an added base. There is no manufacturer's name. The only clue I do have are the initials G R S stamped into the added base. A previous owner's name is also engraved into the top of the gage.

Moving over to the angle plate, I am curious about the partial-length v-grooves and the holes. The photos don't show the holes well. On "Leg A", where the vee grooves exit, there is a hole centered between the grooves. It is 0.2344" diameter for the first 0.875" and then 0.1719" diameter through the rest of the leg. On Leg B, there is a 0.1562" diameter hole parallel to & through the leg's vertical portion. I also find it interesting that the vee grooves themselves are different lengths. The plate itself measures approximately 3-1/8 x 3-1/4 and the thickness of each leg is unequal- one's over 5/8 & one's under.

I could not find any examples of a plate with these grooves. My only possible clues are guesses about the (late) owner's hobbies. I saw shelves full of antique clocks, but no clock parts. The person conducting the sale told me the owner was a hobby gunsmith. I didn't see gun parts or recognizable gun smith's tooling around. I did see reloading equipment. The only other machine tool item I saw was a pair of large vee blacks with clamps, measuring 3-1/2" x 2-3/4" x 5" deep. I bought those, too.

What do you all think these tools are for? Is there a proper name for the base on the surface gage? Also, what is the cross hatching called? I've seen it on other items but never figured out what the correct term is. The grooves in the angle plate are also a curiosity.

Thanks For Your Help!

Paul

PS: Please pardon the dirty workbench. Time to sand the nylon...

I've got a few questions about a surface gage & an angle plate that I recently purchased that I'd like to present here. I have attached 3 photos that should describe the instruments far better than my words can.

The main question that I have about the surface gage concerns the removable base. I'm wondering why this base was added, what it is called and what purpose of the cross hatching on the bottom of it serves. It is attached to the surface gage's base via 3 socket head set screws.

The other question about the base regards its dimensions. The base measures 3.384" wide & 4.000" front-to-rear. It's 1.082" thick (without the added base, which is 0.534" thick.) What would such a large surface gage be used for? I also wonder why the spindle is so short, at 5.178" (0.375" diameter).

In most other respects, it looks 'normal'. There is a vee groove in the bottom, there's a tilt screw & a spindle clamp. There are no hang pins nor is there a

scribe or it's holding clamp.

I can not find this size gage in any of my catalogs, nor can I find one with an added base. There is no manufacturer's name. The only clue I do have are the initials G R S stamped into the added base. A previous owner's name is also engraved into the top of the gage.

Moving over to the angle plate, I am curious about the partial-length v-grooves and the holes. The photos don't show the holes well. On "Leg A", where the vee grooves exit, there is a hole centered between the grooves. It is 0.2344" diameter for the first 0.875" and then 0.1719" diameter through the rest of the leg. On Leg B, there is a 0.1562" diameter hole parallel to & through the leg's vertical portion. I also find it interesting that the vee grooves themselves are different lengths. The plate itself measures approximately 3-1/8 x 3-1/4 and the thickness of each leg is unequal- one's over 5/8 & one's under.

I could not find any examples of a plate with these grooves. My only possible clues are guesses about the (late) owner's hobbies. I saw shelves full of antique clocks, but no clock parts. The person conducting the sale told me the owner was a hobby gunsmith. I didn't see gun parts or recognizable gun smith's tooling around. I did see reloading equipment. The only other machine tool item I saw was a pair of large vee blacks with clamps, measuring 3-1/2" x 2-3/4" x 5" deep. I bought those, too.

What do you all think these tools are for? Is there a proper name for the base on the surface gage? Also, what is the cross hatching called? I've seen it on other items but never figured out what the correct term is. The grooves in the angle plate are also a curiosity.

Thanks For Your Help!

Paul

PS: Please pardon the dirty workbench. Time to sand the nylon...