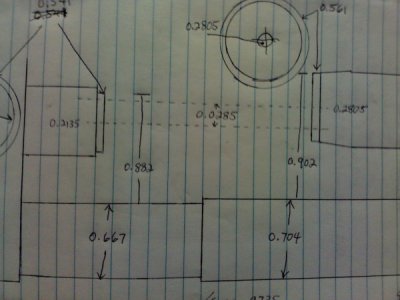

So I have a piston that needs to fit into a cylinder that is offset by 0.0285 in. from the centerline of the piston. My question is to get the needed offset to get the piston to drop the needed amount so that it is centered in the cylinder do I indicate it offset to 0.01425 ?? or do I dial it in at the 0.0285 ?? The difference between the centerlines of both pieces is 0.0285, in other words the cylinder centerline sits 0.0285 below the current centerline of the piston attachment point, so I need to cut the end of the piston shaft as an eccentric to drop the head of the piston enough to center it into the cylinder.

I just need to know if in setting it up in the 4-jaw how I should set the offset to to get the piston centerline to match that of the cylinder. I was watching some tubalcain videos on making an eccentric but wasn't sure if I was understanding the concept correctly... Thanks.

I just need to know if in setting it up in the 4-jaw how I should set the offset to to get the piston centerline to match that of the cylinder. I was watching some tubalcain videos on making an eccentric but wasn't sure if I was understanding the concept correctly... Thanks.