- Joined

- Dec 22, 2011

- Messages

- 310

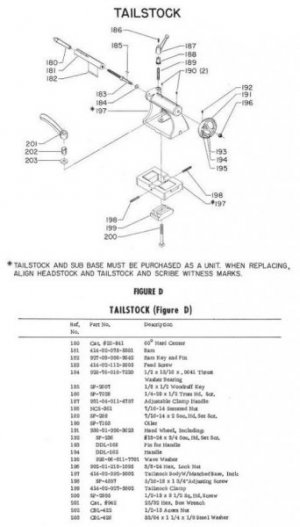

I'm going through the tailstock from a 10" Rockwell metal lathe and in comparing the tailstock I have with the original parts list/diagram, it appears that I am missing part number 147 from the parts list -- a bearing that fits over the end of the feed screw before the feed screw is inserted into the tailstock housing. On the diagram, this bearing doesn't really look like anything more than a washer. The tailstock seems to work fine without it. Is there anyone here that owns one of these lathes that might be able to shed a little more light on what this bearing actually looks like and what purpose it serves? I'd like to find or make a replacement for it if possible. Thanks.