- Joined

- May 21, 2018

- Messages

- 29

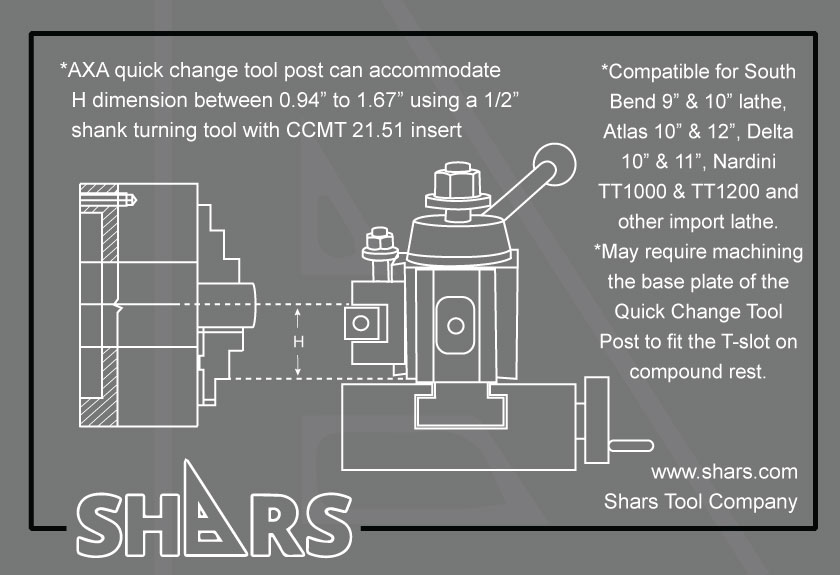

I'm looking to upgrade to a quick change tool post on my 7x12 lathe. Any recommendations on brand. What size is best, cxa, axa, bxa? Wedge or piston style? Any input would be very appreciated!

The name on it is wen, it's the same as the harbor freightWhich 7x12 do you have? Some of them are a pain to mount a QCTP to. And someone might have experience with that model.