- Joined

- Apr 8, 2021

- Messages

- 138

Hello. The only thing letf to have a decent lathe was the quick tool post. The problem is that this is the screw

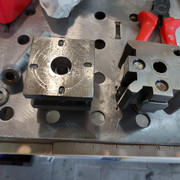

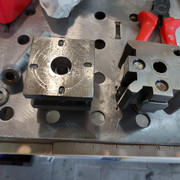

and these are the old tool tool post (left) and the quick tool post (right)

As you can see, I have to machine the base of the new one to allow it to seat on the screw shoulder and I don´t like this idea at all (I´m new in this). So I put a pair of big washers (I have machined the hole for a perfect fit in the shoulder) and now the quick tool post can stand solidly.

The heigh of the tool is OK

What do you think? As I said, I´m new and I don´t have idea whether it is a good solution or an abomination.

Thanky uou.

Kind regards

and these are the old tool tool post (left) and the quick tool post (right)

As you can see, I have to machine the base of the new one to allow it to seat on the screw shoulder and I don´t like this idea at all (I´m new in this). So I put a pair of big washers (I have machined the hole for a perfect fit in the shoulder) and now the quick tool post can stand solidly.

The heigh of the tool is OK

What do you think? As I said, I´m new and I don´t have idea whether it is a good solution or an abomination.

Thanky uou.

Kind regards