- Joined

- Apr 23, 2018

- Messages

- 6,510

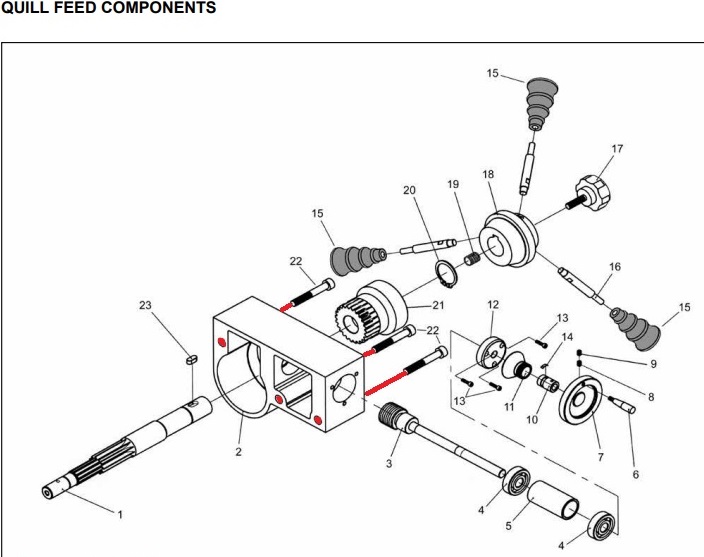

@Driveslayer45 Backlash can be improved by loosening the bolts I marked and sliding the outboard assembly down towards the table. Work the quill feed lever back and forth within the backlash zone while you are adjusting so you can feel what you are doing. Then tighten the bolts back up and check the full range of quill travel for tight spots. There's a happy medium there. Now do the same type of fitting, torquing, aligning, and adjusting to every part that touches another part, and you'll have a decently performing little mill!