H

Hukshawn

Forum Guest

Register Today

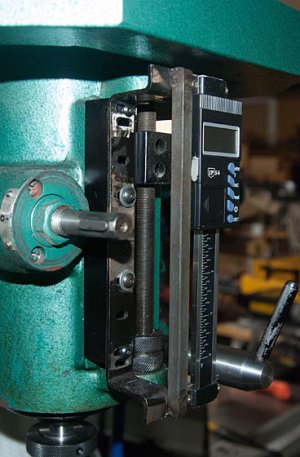

Can the guys that have either a caliper Style scale or a Dro style scale, well I guess any type of scale, take detailed pictures of how they attached the scale to the quill. I have an igaging dro on the quill. I have a small bracket screwed into the side of the depth stop ring and somewhere in my installation there was obviously a bit of tension or Torque because it pulled the tiny screws right out of the back of the dro. And in order to make everything fit I had to do a little bit of nipping and tucking of various surrounding Parts which I wasn't really pleased with. Unfortunately I don't have a picture right now to show.

So I'm looking for some ideas if there's a better way to attach all this.

So I'm looking for some ideas if there's a better way to attach all this.