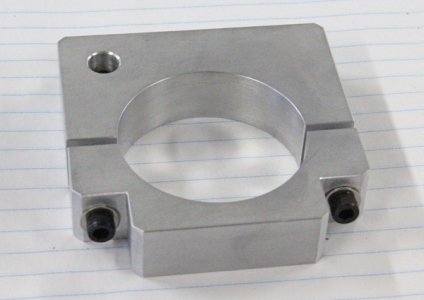

I've wanted a relatively compact & secure, on/off dial test indicator mount for my mill that utilizes my Noga mini arm. These systems are useful to attach to the quill whether there was a tool mounted or not. That means the mount either has to me a split design like what I did, or a single piece clamp on style. My preference was the clamp style but seems like the decent ones are spendy. Replicating the commercial style clamp is a bit of a cutout procedure to make the appropriate shape with contact bumps, recesses & clamp screw etc. Not insurmountable but I figured I'd start with my donut design. For one thing, it doesn't have to fit other quills, just mine. The ID has a lot of contact area so I figure it should clamp very securely.

What I don't really care for on the commercial ones is the link arms are progressively locked knurled nuts or tightening individual cap screws with a hex wrench. Whereas the the Noga arm is very quick. Get the DTI into position & tighten just one knob. Here's what some commercial ones look like

What I don't really care for on the commercial ones is the link arms are progressively locked knurled nuts or tightening individual cap screws with a hex wrench. Whereas the the Noga arm is very quick. Get the DTI into position & tighten just one knob. Here's what some commercial ones look like

Attachments

Last edited: