- Joined

- May 7, 2014

- Messages

- 776

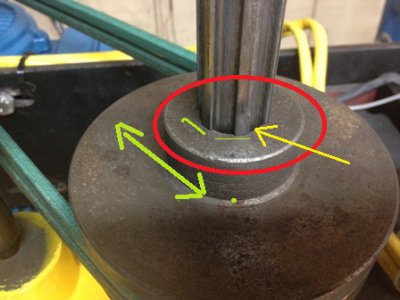

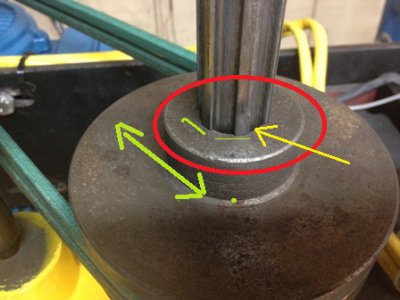

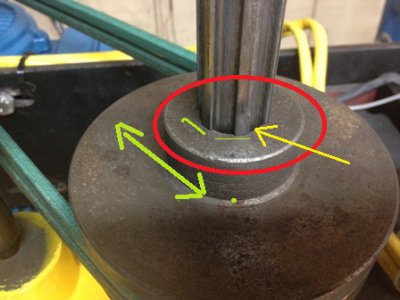

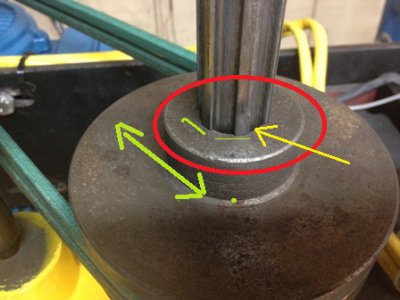

Afternoon gents! Had a quick repair job that I've seen some posting about in a few places . Splines that get play/backlash on the belt-pulley on the Z axis? My machine had 2 terrible backlash problems The first being a CNC ball-screw/quill up/down part strip. Then the spindle and spline w/ spline bore pulley slop causing a 1+ mm rotate slop.

those of you on the site know I went from zero knowledge on Milling to now. So about 3 or 4 months. And have I learned a ton. Goes to show how you must really know how to buy a used machine! In the end, this fix and every other fix was pretty simple, common sense, and easily maintainable if one knows how their machine works.

And have I learned a ton. Goes to show how you must really know how to buy a used machine! In the end, this fix and every other fix was pretty simple, common sense, and easily maintainable if one knows how their machine works.

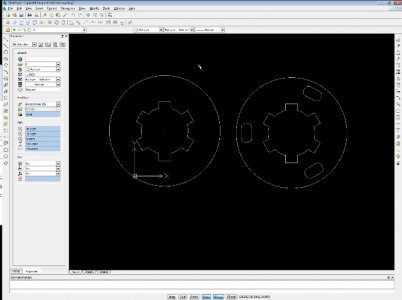

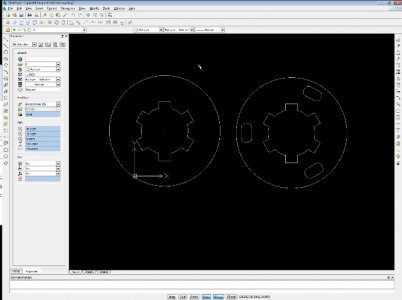

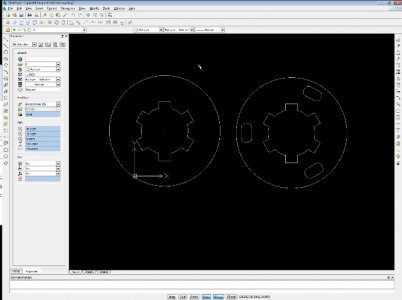

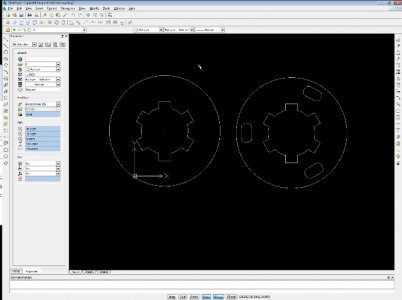

A few pics included below. The fix was to use my Plasma cutter and make a spline cut round token which I could screw down to the pulley after removing the slop. I did find a company called TEA on the east coast (http://www.teausa.net/)that does sell flanged spline bore bushings and shaft in Metric. But these things are really expensive. Being Metric (asian import) finding some items is really hard in the States.

Plasma table to the rescue again! LOVE that thing. Wow! Cut from 1045 steel it should last a long time. Took a few hours to cut, drill and tap everything. Back to running a Mill now at 100% operating effective. Just needs an Operator / programmer now. Ha.! I'm trying.

Anyway, Wanted to post here for the Ether and long lasting Google archives. ;- )

CG

those of you on the site know I went from zero knowledge on Milling to now. So about 3 or 4 months.

A few pics included below. The fix was to use my Plasma cutter and make a spline cut round token which I could screw down to the pulley after removing the slop. I did find a company called TEA on the east coast (http://www.teausa.net/)that does sell flanged spline bore bushings and shaft in Metric. But these things are really expensive. Being Metric (asian import) finding some items is really hard in the States.

Plasma table to the rescue again! LOVE that thing. Wow! Cut from 1045 steel it should last a long time. Took a few hours to cut, drill and tap everything. Back to running a Mill now at 100% operating effective. Just needs an Operator / programmer now. Ha.! I'm trying.

Anyway, Wanted to post here for the Ether and long lasting Google archives. ;- )

CG