- Joined

- Jun 17, 2011

- Messages

- 2,062

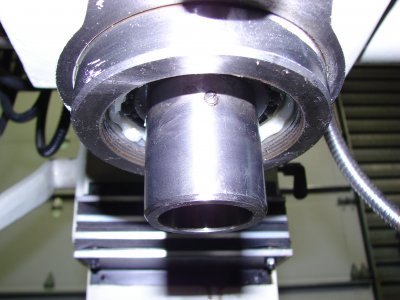

I had the same problem with some R8 tooling in my ZX-25 mill/drill. I figured out that the grooves on some of them were, as mentioned, too shallow. I ended up grinding the pin down just enough to fit the worst of the tools. I've never had any trouble since.

Because the outside diameter of all R8 shanks is the same, within tolerances, the top edge of the groove is in the same place. Works fine with a slightly shorter pin - just not too short.

Because the outside diameter of all R8 shanks is the same, within tolerances, the top edge of the groove is in the same place. Works fine with a slightly shorter pin - just not too short.