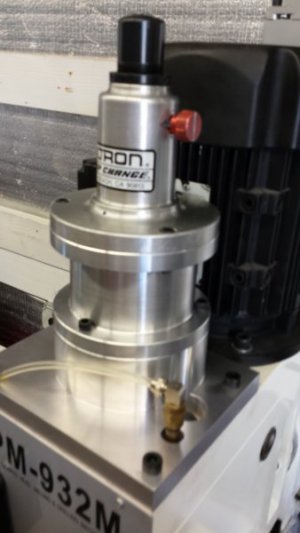

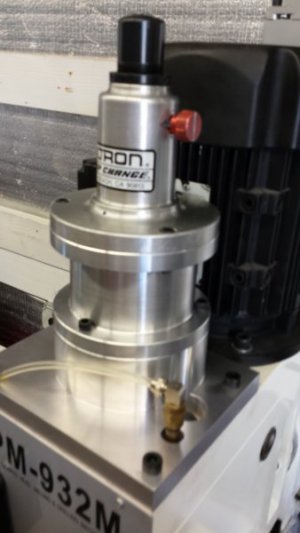

I use the Ultron Snap Change system. Here's the website snapchange.com/. It's a simple system that uses about 1" of spindle travel to change a collet. No adapters or power drawbar are needed.

The kit I bought was for a Bridgeport so I had to replicate the distance from the spindle nose to the drawbar seating surface on top of the spindle thus the need for the adapter plate and spool pictured below.

This is the kit I bought. It came with the special drawbar, the collet gripper, the rotation sensor (aluminum piece on the left), and 12 assorted collets.

The kit I bought was for a Bridgeport so I had to replicate the distance from the spindle nose to the drawbar seating surface on top of the spindle thus the need for the adapter plate and spool pictured below.

This is the kit I bought. It came with the special drawbar, the collet gripper, the rotation sensor (aluminum piece on the left), and 12 assorted collets.