While not exactly related to supporting the fleet boats, this project was more about improving throughput on the Traeger smokers. Lots of space above the grill for more fish, so to fill that space with additional smoking racks required a rack stacker. Smoked lake trout and whitefish are superb and demand is increasing.

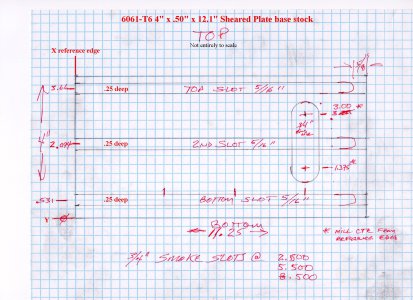

Seven hours on the mill to make two stackers, each with two side plates. Truing the vise, locating the first piece and setting the reference edges on the DRO took some time. Milling the first side plate took a while also because the process required some method adaption in plunge cutting and slotting out the smoke ports. No 2-flute end mills on hand yet (back-ordered) and slotting with 4-flutes is kind of slow. First plate = three hours. Next three = four hours. A lot of chips.

Seven hours on the mill to make two stackers, each with two side plates. Truing the vise, locating the first piece and setting the reference edges on the DRO took some time. Milling the first side plate took a while also because the process required some method adaption in plunge cutting and slotting out the smoke ports. No 2-flute end mills on hand yet (back-ordered) and slotting with 4-flutes is kind of slow. First plate = three hours. Next three = four hours. A lot of chips.