- Joined

- Dec 23, 2019

- Messages

- 1,138

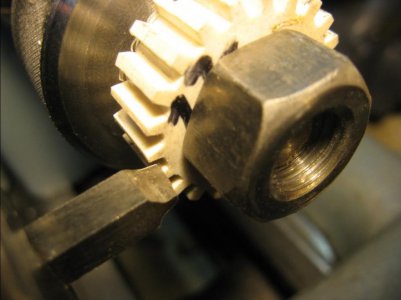

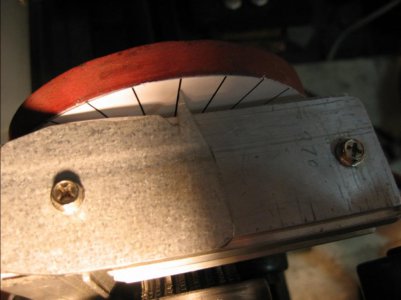

Phenolic is cheap, easy to work and a great material for change gears. Just get the sheet, not the rolled bar stuff.

Master Gotteswinter on the subject of making change gears:

I really enjoy making gears, it's one of my favourite operations on the mill.

Master Gotteswinter on the subject of making change gears:

I really enjoy making gears, it's one of my favourite operations on the mill.