-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rebarrel small ring 95 mauser

- Thread starter mickri

- Start date

- Joined

- Sep 19, 2019

- Messages

- 109

Brownells sells Cerrosafe for that, much lower melting point & less shrinkage and reusable.There's no way to know what the pitch diameter should be.........it's completely oddball. Threading till it fits will work, as long as the thread form is correct. You could do a lead cast of the receiver threads for comparison.

080027050 | Brownells

Brownells is your source for 080027050 at Brownells parts and accessories. Shop our vast selection and save!

- Joined

- Oct 31, 2016

- Messages

- 2,643

I used some modeling clay I had on hand to check the receiver threads. Came out good enough to determine that the threads were 12 tpi whitworth. I ground a tool bit to the whitworth thread form including the nose radius.

We needed to rebarrel a number of these that came as surplus with very bad bores plus others customers bourht in for repair, Given a combination of NOS barrels and some blanks we didn not get the job done without some hitchs. Unlike most 98s we found that M95 Chilean receivers can be very, very soft. Extreme care must be taken not to bend them in any way and mis align the bolt ways. I mention it here as it is possible to use excessive turning force when rebarreling or to accidenlly exert downward pressure on the tang. Dropping one can on the tang end can do it too. Forcing the wrong size or pitch threaded barrel has also happened. Have had several which would either bind or even not close without force. Once bent the odds are against ever getting it right again.

I think i may know why your M95(s) came without barrels. When Century bought in what seemed to be the entire contents of the Chilean Arsenals many had bad bores and price was absurdly low. In reality good barrels were worth more than actions and bad barreled actions were worth even less. Good barrels got sold separately or used to replace bad ones. Bad barrels got yanked and scrapped to boost action sales. We got caught in middle and tried to make the best of what we had to work with. Even now nice small ring barrels still bring a premium so much so some may have taken to turning down and rethreading surplus LR barrels off of 7mm 1908 brazilians and the like. The cost of new SR barrels seems very tall to me and surprised to see that Chinese ones aren't a thing yet.

Should add bolt binding is a quick check other checks with flat rules and mics are confirmation.

Should add bolt binding is a quick check other checks with flat rules and mics are confirmation.

- Joined

- Oct 31, 2016

- Messages

- 2,643

Noticed you joined the forum last month. Welcome. We are a friendly bunch that welcomes everyone.

The bolts open and close with no problems that I can see on my actions. I'll put them in the vice on the mill and run a DI along the bolt races and anywhere else that I think I can get a reading.

The bolts open and close with no problems that I can see on my actions. I'll put them in the vice on the mill and run a DI along the bolt races and anywhere else that I think I can get a reading.

New here but smithing since late 70's. Sometimes the issue comes up after a new barrel is fitted, headspaced and installed in new stock. Bad fitting on the rear tang screw can be a problem. One came in that had been fine in Military stock and bound up in new sporter stock. Seems owner did not think the rear metal spacer tube was necessary. .

- Joined

- Oct 31, 2016

- Messages

- 2,643

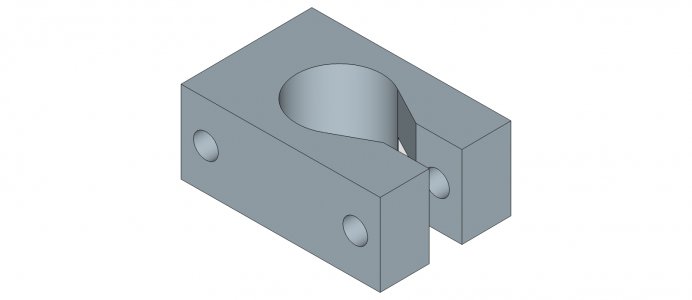

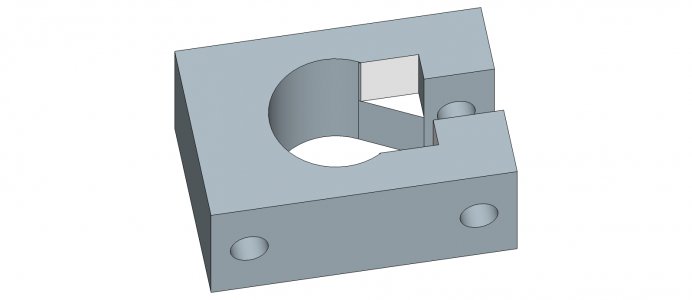

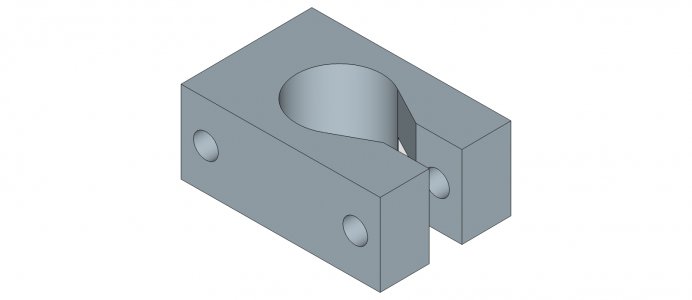

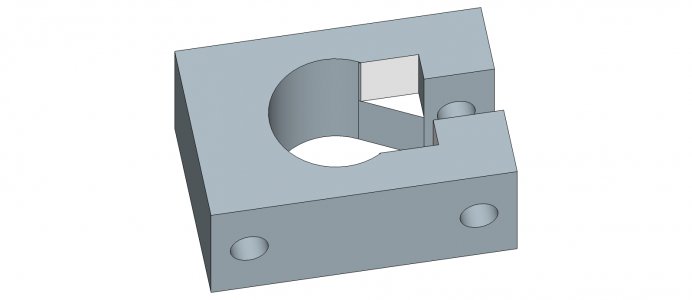

Waiting for stuff to arrive on other projects so had time to do other things. After cleaning up the lathe, mill, band saws and the sweeping the floor I started on the action wrench that I need for the small ring mausers and the carcano. Whenever I start a project I do a 3d model. Here is the model of the action wrench.

One side fits the carcano receiver and the other side fits the mauser receiver. The OD of both receivers are within a about .010 with the carcano being slightly larger than the mauser. I got the idea for this from an action wrench posted in another thread here on the forum.

Laid it out on some 2 x 1.25 1018 flat bar I have and cut it off in the 3x6 band saw. Normally I would bore the hole in the lathe and then move over to the mill to do the slots. This time I decided to do everything on the mill. Wanted to give my poor man's rotary table a work out. I have the coordinates to center the rotary table posted on the head. All I had to do was move the table to the coordinates. Put my 6" 4 jaw on the rotary and dialed in the work with a sharp pointed countersink. Moved the mill table over so that a 3/8 drilled hole would be just inside the ID of the hole. Then spun the rotary table to scribe a line as a visual check that my set up was ok.

That's all I got done this afternoon before the cold in the garage drove me inside to warm up.

One side fits the carcano receiver and the other side fits the mauser receiver. The OD of both receivers are within a about .010 with the carcano being slightly larger than the mauser. I got the idea for this from an action wrench posted in another thread here on the forum.

Laid it out on some 2 x 1.25 1018 flat bar I have and cut it off in the 3x6 band saw. Normally I would bore the hole in the lathe and then move over to the mill to do the slots. This time I decided to do everything on the mill. Wanted to give my poor man's rotary table a work out. I have the coordinates to center the rotary table posted on the head. All I had to do was move the table to the coordinates. Put my 6" 4 jaw on the rotary and dialed in the work with a sharp pointed countersink. Moved the mill table over so that a 3/8 drilled hole would be just inside the ID of the hole. Then spun the rotary table to scribe a line as a visual check that my set up was ok.

That's all I got done this afternoon before the cold in the garage drove me inside to warm up.

Nice work but barrel work can be really tough on tooling. Tried some of the off the shelf vises and wrenchs and about broke them all. Attached are some pics of current equipment. Sometimes even small ring mausers can be as tough as the infamous P14/17s to work on. My wrench and vise is crude but has done several hundred jobs but still needs occaisional repairs due to stress involved. Dubbed "HFS" by a good friend (hell for stout) most barrels come right off as "resistance in futile" with a 3 foot cheater. Barrel inserts are turned for each type of barrel from 2" aluminum and up to 5' pf cheater can be used. Care must be taken as when she comes loose it can happen fast and without warning.