OK, the long title says it all, I have an older southbound mill that I really enjoy, it's heavy, only has 1 hp, but she is pretty solid and a ram head. No nod, but she does tilt side to side.

OK, the long title says it all, I have an older southbound mill that I really enjoy, it's heavy, only has 1 hp, but she is pretty solid and a ram head. No nod, but she does tilt side to side.I am in the process of collecting information on what I am going to need to do to rebuild the head and replace the spindle bearings on this machine. The information on this machine is a little sparse, though, not much is needed because the machine is fairly straight forward in design and construction.

Any info you might be aware of I'd would apperciated, very interested in info on taking apart the head and any adjustments alignments I should be aware of before I start pulling her apart.

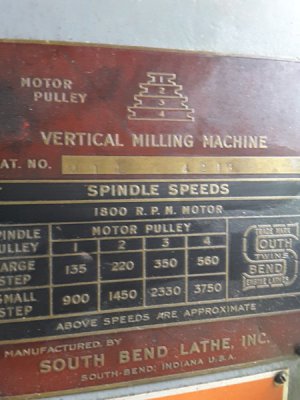

Some pictures of the machine , head and the name plate.

View attachment 242089