- Joined

- Feb 2, 2014

- Messages

- 1,054

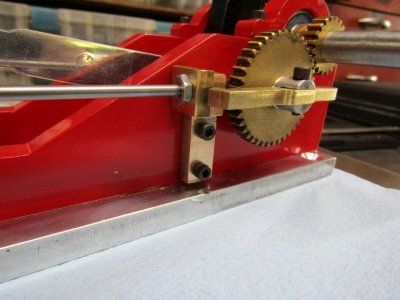

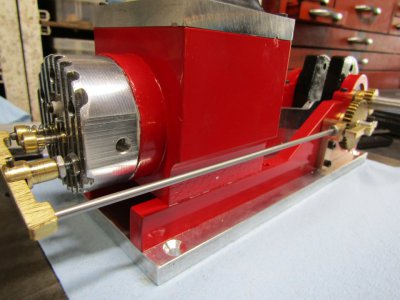

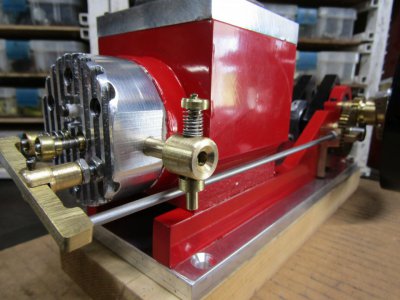

Brian thank you for the kind words but I do have an advantage. I try to design my engines in such a way as to use some parts I have already made for other engines for this engine. Take the cylinder head as an example. Except for some minor changes it is the same head as I have used on two other models. The timing gears and cam lobe is the same as three other engines I have built so it saves a lot of time.

Robert and frankly2 the top hat is mainly for cosmetic purposes. It will help to keep the water from splashing out and it does hide any mistakes I may have made when I milled out the water jacket.

But actually I just like it!

Lapped the valves and pressure tested them with shop air in a test plate.

Made the valve spring retainers and the intake valve spring from 0.010 music wire.

Thanks for looking

Ray

Robert and frankly2 the top hat is mainly for cosmetic purposes. It will help to keep the water from splashing out and it does hide any mistakes I may have made when I milled out the water jacket.

But actually I just like it!

Lapped the valves and pressure tested them with shop air in a test plate.

Made the valve spring retainers and the intake valve spring from 0.010 music wire.

Thanks for looking

Ray