- Joined

- Jul 6, 2021

- Messages

- 12

Hello everyone.

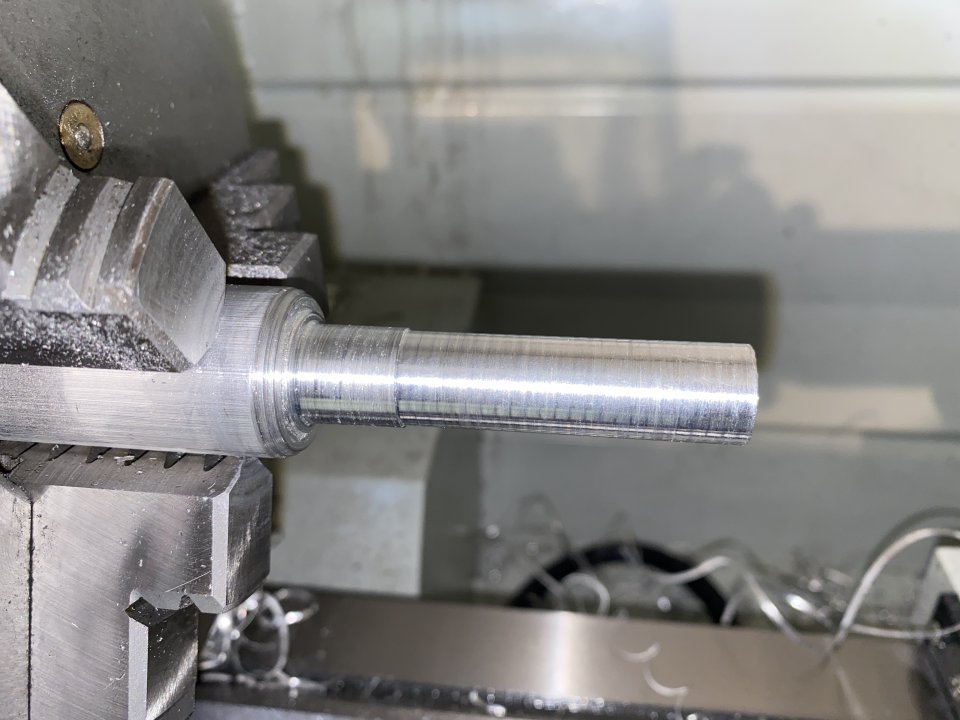

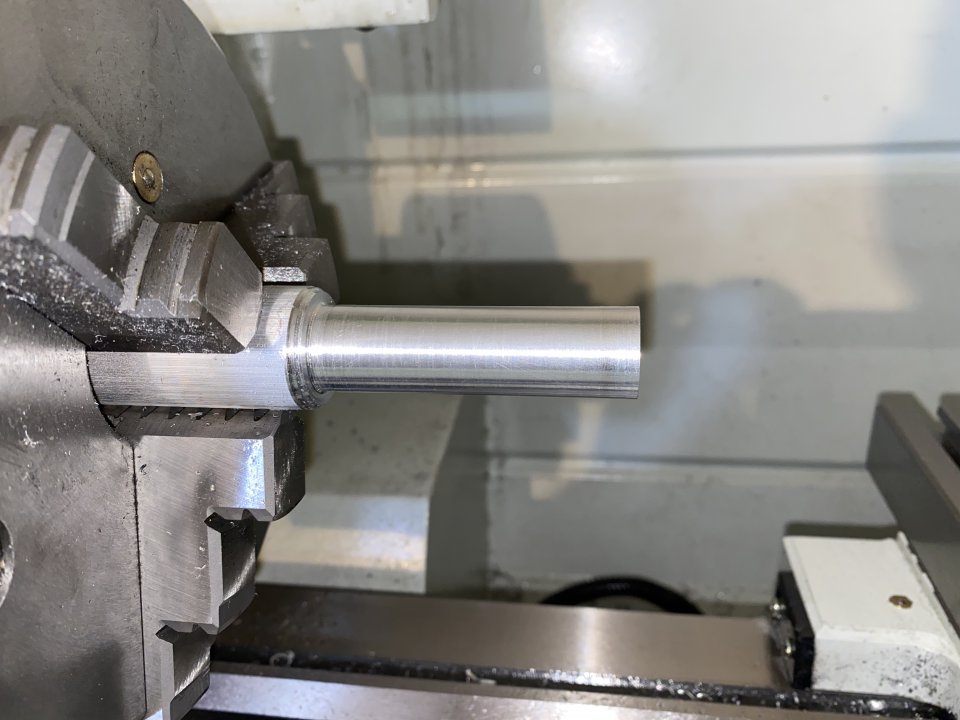

When running the power feed, the lathe creates regular ripples on the surface that are measurable high spots. When feeding using the lead screw, the ripples are not present. I've tried a wide range of speeds, feeds, DOC, tool geometry, and two materials (12L14, 6061 AL). No matter what, the ripples have persisted.

PM replied that it must be user error and told me to post here so here I am. I was really hoping PM would have more insight. The "less friendly forum" has a thread on this topic. Not sure if I'm allow to link to it here. I sent PM that link and they told me the pinion issue was unlikely.

To be clear, I'm not talking about the difference in surface finishes common with speeds, feeds, and tool geometries. These ripples are regular at the same spacing for all cutting conditions under power feed. When feeding with the lead screw or by hand the finishes are great and no ripples are present.

Any guidance of suggestions would be appreciated.

Powerfeed, .0025/rev (slowest), 6061 AL

Leadscrew, .004/rev, 6061 AL

When running the power feed, the lathe creates regular ripples on the surface that are measurable high spots. When feeding using the lead screw, the ripples are not present. I've tried a wide range of speeds, feeds, DOC, tool geometry, and two materials (12L14, 6061 AL). No matter what, the ripples have persisted.

PM replied that it must be user error and told me to post here so here I am. I was really hoping PM would have more insight. The "less friendly forum" has a thread on this topic. Not sure if I'm allow to link to it here. I sent PM that link and they told me the pinion issue was unlikely.

To be clear, I'm not talking about the difference in surface finishes common with speeds, feeds, and tool geometries. These ripples are regular at the same spacing for all cutting conditions under power feed. When feeding with the lead screw or by hand the finishes are great and no ripples are present.

Any guidance of suggestions would be appreciated.

Powerfeed, .0025/rev (slowest), 6061 AL

Leadscrew, .004/rev, 6061 AL