I have an Atlas DP similar to this one. The Jacobs 6A chuck could use some help but I'm having trouble getting it off. I used a set of wedges and all is seems to do is increase the gap between the chuck and the 2 rings above it. The spline seems to be pulling down as the gap increases. What am I doing wrong here?

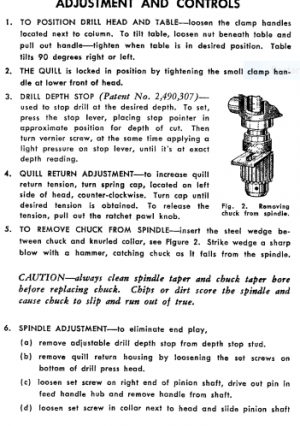

Thanks.