- Joined

- Oct 13, 2020

- Messages

- 10

Hi Everyone,

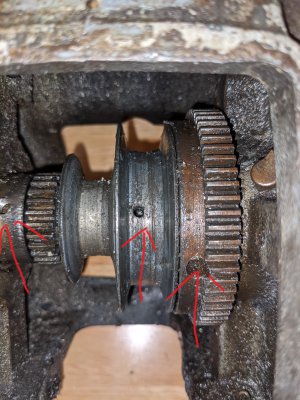

I have an atlas mill that's in a pretty sorry state. I'm taking apart cleaning & repainting. Problem is the spindle is totally stuck in the headstock. The spindle spins freely in the bearings, the locking collar unscrewed from the back easily. I've removed set screws from the collar inside the headstock and the gear inside the headstock. The gears, pulley and collars inside the head stock all slide up and down the shaft freely. But the spindle will not budge. I see you need to be careful to line the key up with the notch in the headstock when removing, but every video I can find shows it coming out with a light tap. As best I can tell from knocking mine with a hammer and a block of wood it doesn't move a fraction of an inch. Any ideas on getting it out?

I have an atlas mill that's in a pretty sorry state. I'm taking apart cleaning & repainting. Problem is the spindle is totally stuck in the headstock. The spindle spins freely in the bearings, the locking collar unscrewed from the back easily. I've removed set screws from the collar inside the headstock and the gear inside the headstock. The gears, pulley and collars inside the head stock all slide up and down the shaft freely. But the spindle will not budge. I see you need to be careful to line the key up with the notch in the headstock when removing, but every video I can find shows it coming out with a light tap. As best I can tell from knocking mine with a hammer and a block of wood it doesn't move a fraction of an inch. Any ideas on getting it out?