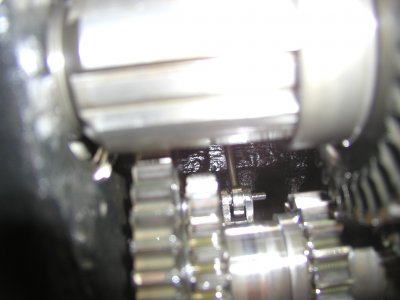

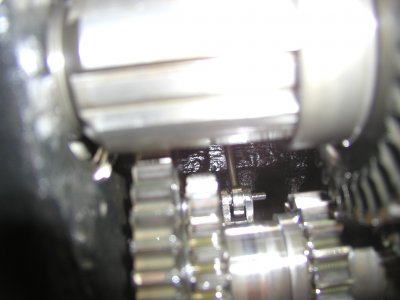

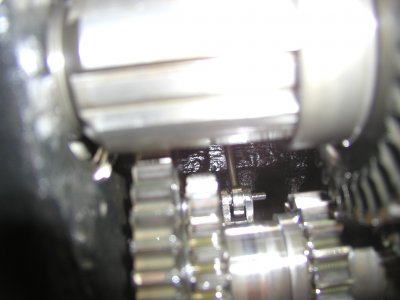

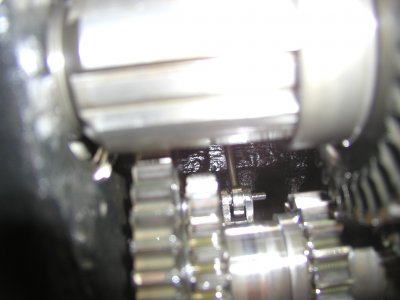

The "pump operating lever cam roll" in the spindle transmission case on my B&S #2 plain mill has separated into its component pieces - ball bearings and shreds of the cage. Unfortunately it is difficult to get to in place and I have not had much success in removing it. I plan instead to remove the "pump operating lever" entirely but to do so requires removing the "pump operating lever stud" which is held by a set screw and is perhaps threaded and in any case looks as if removing it requires removing the spindle motor.

I removed all 4 nuts holding the spindle motor onto the frame but have had zero luck in separating the motor from the frame - it refuses to budge!

I don't see any set screws on the motor shaft (in fact I can't see the motor shaft at all) and I would rather not remove the "brake operating yoke shaft" or any other brake parts unless required to remove the motor. Someone else n another forum had a question about removing the spindle motor a was referred to the Ron Peisker video, which shows no detail at all.

Does anyone know the proper procedure for removing the spindle motor?

I removed all 4 nuts holding the spindle motor onto the frame but have had zero luck in separating the motor from the frame - it refuses to budge!

I don't see any set screws on the motor shaft (in fact I can't see the motor shaft at all) and I would rather not remove the "brake operating yoke shaft" or any other brake parts unless required to remove the motor. Someone else n another forum had a question about removing the spindle motor a was referred to the Ron Peisker video, which shows no detail at all.

Does anyone know the proper procedure for removing the spindle motor?