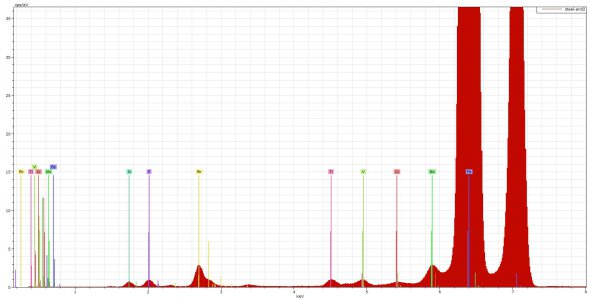

A coworker asked if i could join the two parts of an antique coffee grinder bolt. The cat knocked it off the mantle. I'm not sure if siver brazing is the best choice and what alloy braze. I have access to an XFR, to analyze the metal content. Attached is the bolt and the XFR analysis. It can't see anything lower than sodium, so no carbon. I'm wondering if this is enough to tell what it is. If we really need the carbon content I'll see if I can get an SEM scan.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Repair a broken antique coffee grinder bolt

- Thread starter KMoffett

- Start date

- Joined

- Mar 19, 2014

- Messages

- 2,680

I would turn down the shank of the head part. This saves the look of the carriage bolt type head. Make a new lower part with the square and threads and a hole for the shank of the head part. Then Loctite the two together. XFR analyze/report…SEM scan…WOW!

- Joined

- Dec 12, 2016

- Messages

- 493

Given that the original apparently snapped it must be under some tension, maybe too much.

Silver solder or braze might not be strong enough.

You could TIG it back together with steel and it might be as strong as new, and then keep the Gorillas away from it!

If TIG does not work fallback is fabricate a new one from appropriate bar stock.

Silver solder or braze might not be strong enough.

You could TIG it back together with steel and it might be as strong as new, and then keep the Gorillas away from it!

If TIG does not work fallback is fabricate a new one from appropriate bar stock.

- Joined

- Jan 2, 2014

- Messages

- 8,851

If final length and strength is not critical, I would:

1) on the lathe chuck, face and drill each piece,

2) tap the holes,

3) join with a suitable piece of threaded rod (maybe #10-32) and lock-tite

-brino

EDIT: test with a dry fit; if the two squares on the top and bottom shanks need to align, just face a little off one side until it's perfect.

1) on the lathe chuck, face and drill each piece,

2) tap the holes,

3) join with a suitable piece of threaded rod (maybe #10-32) and lock-tite

-brino

EDIT: test with a dry fit; if the two squares on the top and bottom shanks need to align, just face a little off one side until it's perfect.

Last edited:

- Joined

- Feb 6, 2017

- Messages

- 104

I would center it like brino say's, bevel the edges and tig it with silicon bronze filler and turn it back to diameter.

PERSONALLY... if you have lathe and mill, I’d just make a new one out of something like 4140 steel.

Silver solder braze just not strong enough for a tensioned bolt and also silver braze really needs to be super clean. So you’re going to need to grind both ends.

It doesn’t look hard to make a new one in my opinion.

By the, just guessing here but due to the square sections plus the adjust type of nut, I’m guessing this bolt is for the crank handle and the level of grind is regulated by tightening that nut.....kind of like pepper grinders, you tighten the nut to make the grind finer. Seems more troublesome to repair than making a new one. Easy enough to make it look old. Like mentioned above oil burning does a decent job of aging steel.

Silver solder braze just not strong enough for a tensioned bolt and also silver braze really needs to be super clean. So you’re going to need to grind both ends.

It doesn’t look hard to make a new one in my opinion.

By the, just guessing here but due to the square sections plus the adjust type of nut, I’m guessing this bolt is for the crank handle and the level of grind is regulated by tightening that nut.....kind of like pepper grinders, you tighten the nut to make the grind finer. Seems more troublesome to repair than making a new one. Easy enough to make it look old. Like mentioned above oil burning does a decent job of aging steel.

Last edited:

- Joined

- Jul 29, 2014

- Messages

- 2,725

Is that XFR from Harbor Freight? I could use one of them.

No. They got a deal on the a used one. Only $140,000.00Is that XFR from Harbor Freight? I could use one of them.

Thanks for all the advise. I wound up silver soldering it. Ground both faces flat. For alignment I mounted the bolt's head-end in a 3-jaw chuck in a lathe. Mounted the threaded end in a tailstock chuck. While separated, I fluxed and tinned each face. Then fluxed, reheated, and pushed together. Looks like this will work. I don't think I mentioned that this coffee grinder is only used as a ornament.