4

4GSR

Forum Guest

Register Today

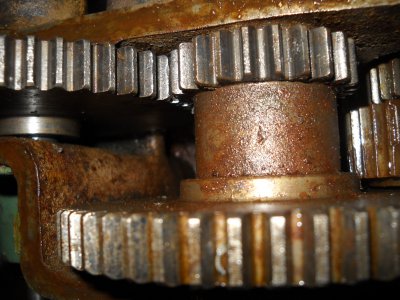

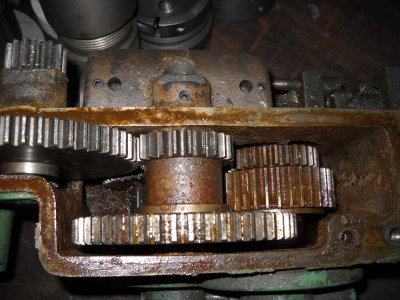

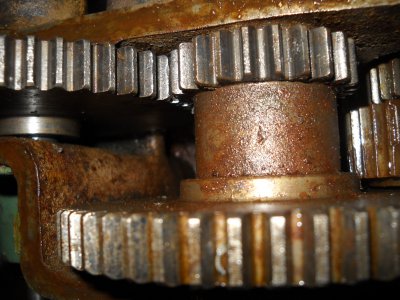

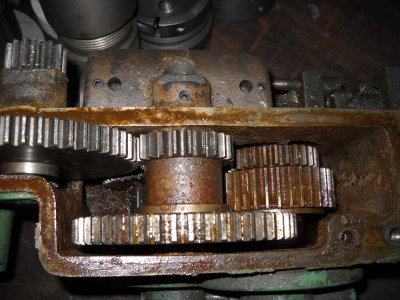

I bought a 15" Sheldon lathe this past year and has been storage since then. I pulled the apron and carriage off the lathe stored in my shop until I can make room for the lathe. Meantime, I started cleaning up the apron over the holidays and have many repairs that need to be made to the apron. The lathe was born around 1960-1961 from what I've been able to find out. It is a Model ER60P serial number 25267. It is the model with the two lever QC gear box and single rod apron. The apron looks like it left the factory without any oil. Most everything in the apron is rusty, full of shavings and a lot of plastic shavings stuffed in there. There are two plate type clutches, one is salvageable and the other one is trashed out. Luckily I have a set of clutch plates I bought many years ago for my other Sheldon lathe for a backup set that will get used. You can still get the clutch plates from Carlyle Johnson Machine Co. for a hefty price! I may still buy another clutch pack to keep on hand. Here are some pictures of "before" and pictures of some of the repairs I'm doing now. Enjoy!