- Joined

- Aug 22, 2012

- Messages

- 4,101

A couple of years ago my 25x100 binocular fell out the back of a truck (fell out not fell off the back of) and broke in half.

A club member had a go at welding the little broken pieces back together but unfortunately not very well.

I was just going to keep then as individual finder scopes for my giant binocular (when I get back to making it) but yesterday I felt like a break from the powder coating oven and decided to see if I could repair them.

I had disassembled them two or more years ago so cant remember exactly how they go back together.

This is the broken ring

This is the repaired ring that doesnt look as if it will last very long

The fixing holes at the wide end are oval for some reason, I can only think that the two tubes do not move entirely parallel with each other and this is for clearance but I dont know for sure.

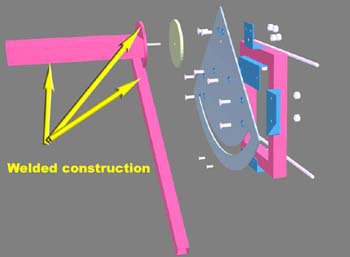

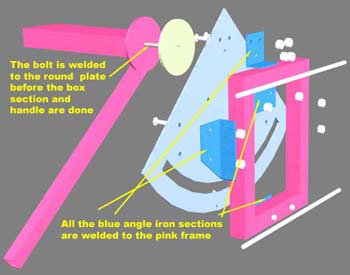

After some experimentation it looks as if all the parts go together like this.

The small screws are to hold the prisms in the housing.

I think there is sufficient material to allow two new side plates to be screwed to the broken originals so I'm making a mandrel to pass through all four fixing rings to spot the centres of the new plates.

I will bore these to size as all four are slightly different diameters as the main fixing pin is tapered.

The spacer will then have to be shortened to fit in between them also.

I hope I can get them close enough to original as re-aligning the optical assemblies will be a difficult one.

Translation - I've never done this before.

A club member had a go at welding the little broken pieces back together but unfortunately not very well.

I was just going to keep then as individual finder scopes for my giant binocular (when I get back to making it) but yesterday I felt like a break from the powder coating oven and decided to see if I could repair them.

I had disassembled them two or more years ago so cant remember exactly how they go back together.

This is the broken ring

This is the repaired ring that doesnt look as if it will last very long

The fixing holes at the wide end are oval for some reason, I can only think that the two tubes do not move entirely parallel with each other and this is for clearance but I dont know for sure.

After some experimentation it looks as if all the parts go together like this.

The small screws are to hold the prisms in the housing.

I think there is sufficient material to allow two new side plates to be screwed to the broken originals so I'm making a mandrel to pass through all four fixing rings to spot the centres of the new plates.

I will bore these to size as all four are slightly different diameters as the main fixing pin is tapered.

The spacer will then have to be shortened to fit in between them also.

I hope I can get them close enough to original as re-aligning the optical assemblies will be a difficult one.

Translation - I've never done this before.