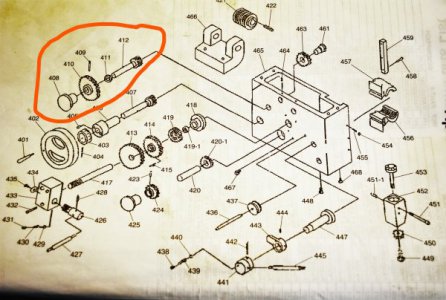

I just did that with mine a few weeks ago. Running the carriage back toward the tail stock with the lead screw to distribute oil after cleaning. It came to an abrupt stop about 4" before contacting the tail stock and was rough moving under power after that. I got to looking and the shaft for the change levers was bent. I think one of the other shafts in the change gear box was bent also, causing the gear train to bind up in some positions. The gears were all fine. I ordered all three new shafts, one is on back-order.

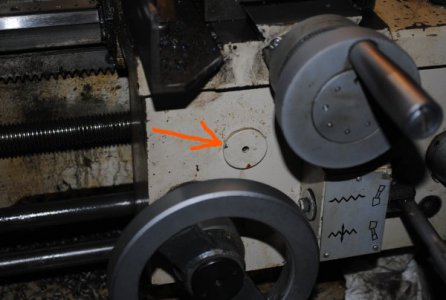

I'm pretty sure the hole in the rear bearing block is misaligned for the lead screw and caused it to bind when it got near the end.