- Joined

- Mar 16, 2016

- Messages

- 132

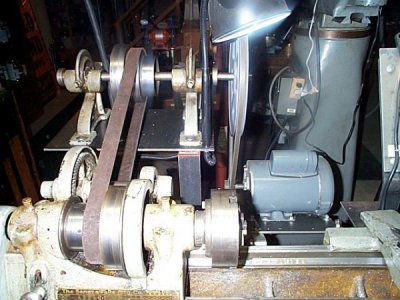

My old Lathe is in need of more power and I am unaware of how much power I can bring on board or how much the belts can handle.

I was thinking along the lines of a 3 HP single phase 220 motor.

Will I kill it with that?

I was thinking along the lines of a 3 HP single phase 220 motor.

Will I kill it with that?