- Joined

- May 28, 2014

- Messages

- 20

Just a quick update:

The bushings are out using the locknut technique. Thank you, stevejw!

There a little tongue, making sure the slot is always turned upward toward oiling hole. Also, looks like someone was boring through the oil hole, and hit the bushing...retards...

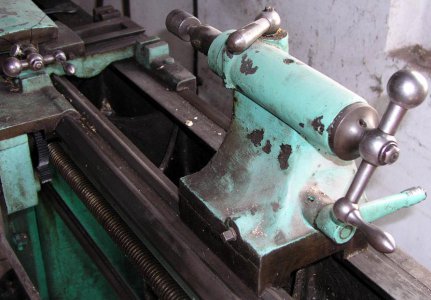

Also, I took on cleaning of the composite slide, cross slide, saddle and ways. All but the ways turned out ok, but the ways are too heavily damaged by rust. I guess i'll have to go the electrolysis way :/

As you will see the tool clamp is something ancient, I'm considering buying a QCTP, cause this one is ridiculous. Also, the non-machined parts of the cross-slide were painted with some devilish color that doesn't want to come off. I even tried wire brush. Should i just paint over it, or should i use a hand-held grinder with emery-paper? I'm afraid i don't damage the machined parts :/

There's an angle protractor on the cross slide, but there is no notch on the composite slide to align it with

I'm still left with cleaning tail stock and an apron, but that will have to wait until i get back from vacation.

Btw, there is a taper in the spindle, i can't discern if its original or if someone was playing with it... the finish by no means smooth... what do you guys think?

Here are some pictures.

The bushings are out using the locknut technique. Thank you, stevejw!

There a little tongue, making sure the slot is always turned upward toward oiling hole. Also, looks like someone was boring through the oil hole, and hit the bushing...retards...

Also, I took on cleaning of the composite slide, cross slide, saddle and ways. All but the ways turned out ok, but the ways are too heavily damaged by rust. I guess i'll have to go the electrolysis way :/

As you will see the tool clamp is something ancient, I'm considering buying a QCTP, cause this one is ridiculous. Also, the non-machined parts of the cross-slide were painted with some devilish color that doesn't want to come off. I even tried wire brush. Should i just paint over it, or should i use a hand-held grinder with emery-paper? I'm afraid i don't damage the machined parts :/

There's an angle protractor on the cross slide, but there is no notch on the composite slide to align it with

I'm still left with cleaning tail stock and an apron, but that will have to wait until i get back from vacation.

Btw, there is a taper in the spindle, i can't discern if its original or if someone was playing with it... the finish by no means smooth... what do you guys think?

Here are some pictures.