- Joined

- Mar 20, 2014

- Messages

- 418

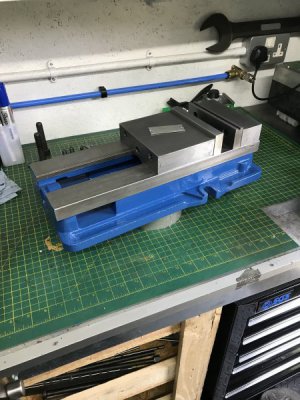

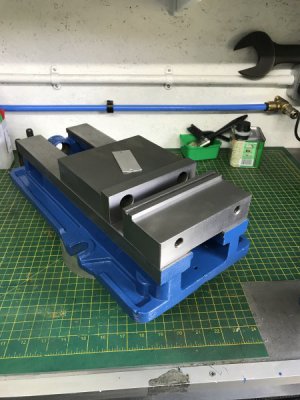

I managed to get a used D688 on eBay, and I’m going to restore it.

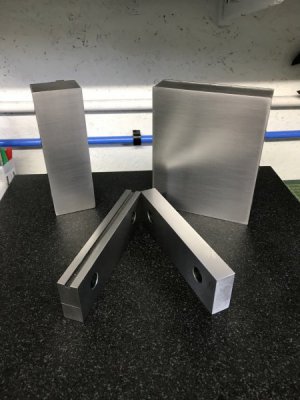

I’ve already remachined the tops of the jaws, to get rid of all the gouges and dings:

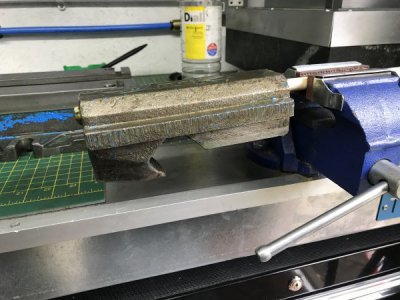

And now I’ve managed to completely strip it down. Here’s the state of all the service items. Good job they’re all being replaced. Yuck.

The screw and nut look good, and the hardwear is currently relaxing in an evaporust spa tub along with the fixed jaw, to remove surface rust.

A couple of queries though before I start doing anything else. All of the cap head screws on it have head metric sized hex sockets. The large ones for the fixed jaw are 14mm - I ended up using this and a 17mm socket / breaker bar combo to remove them.

Is that normal for imperial / English sized fasteners?

And the serial number plate is held on with drive screws. Opinions on the best way to remove them? Or just mask over when I repaint the body as all that’s left on it is the punched numbers.

I’ve already remachined the tops of the jaws, to get rid of all the gouges and dings:

And now I’ve managed to completely strip it down. Here’s the state of all the service items. Good job they’re all being replaced. Yuck.

The screw and nut look good, and the hardwear is currently relaxing in an evaporust spa tub along with the fixed jaw, to remove surface rust.

A couple of queries though before I start doing anything else. All of the cap head screws on it have head metric sized hex sockets. The large ones for the fixed jaw are 14mm - I ended up using this and a 17mm socket / breaker bar combo to remove them.

Is that normal for imperial / English sized fasteners?

And the serial number plate is held on with drive screws. Opinions on the best way to remove them? Or just mask over when I repaint the body as all that’s left on it is the punched numbers.