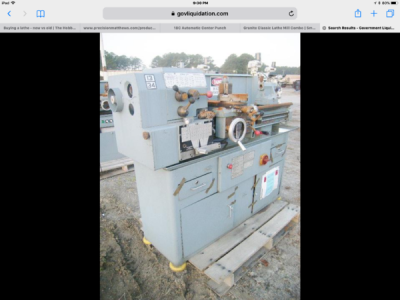

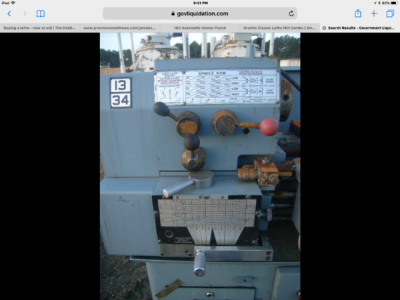

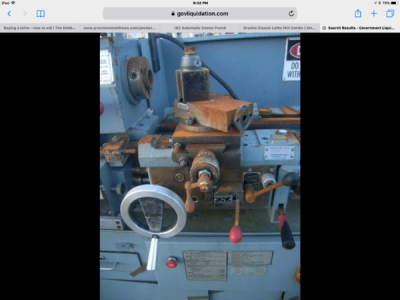

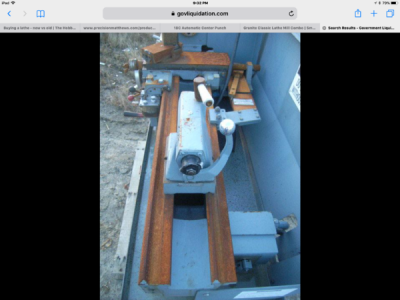

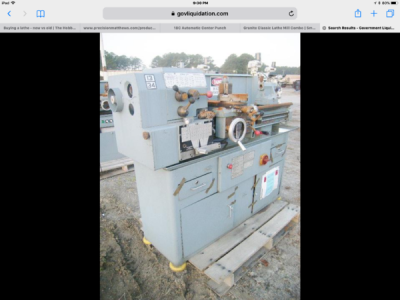

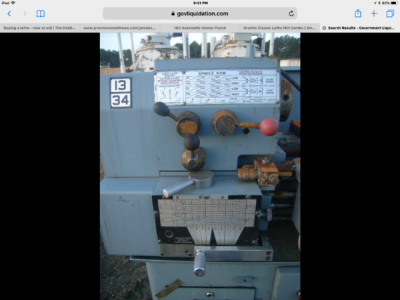

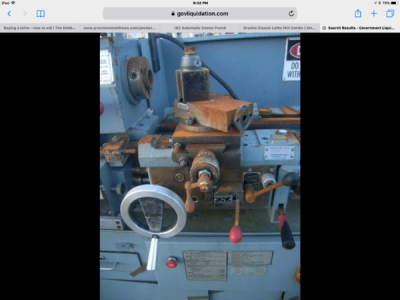

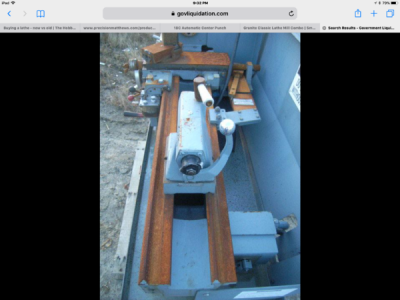

Hello Folks! I am interested in restoring, or attempting to restore an old Standard Modern. I have some photos here of one in an auction. Does anyone know if this is too far gone or is it worth a try to bid on something like this? If so, what would be a good offering bid? Thanks for your opinion!

Steve

Steve

Last edited: