- Joined

- Jul 6, 2022

- Messages

- 498

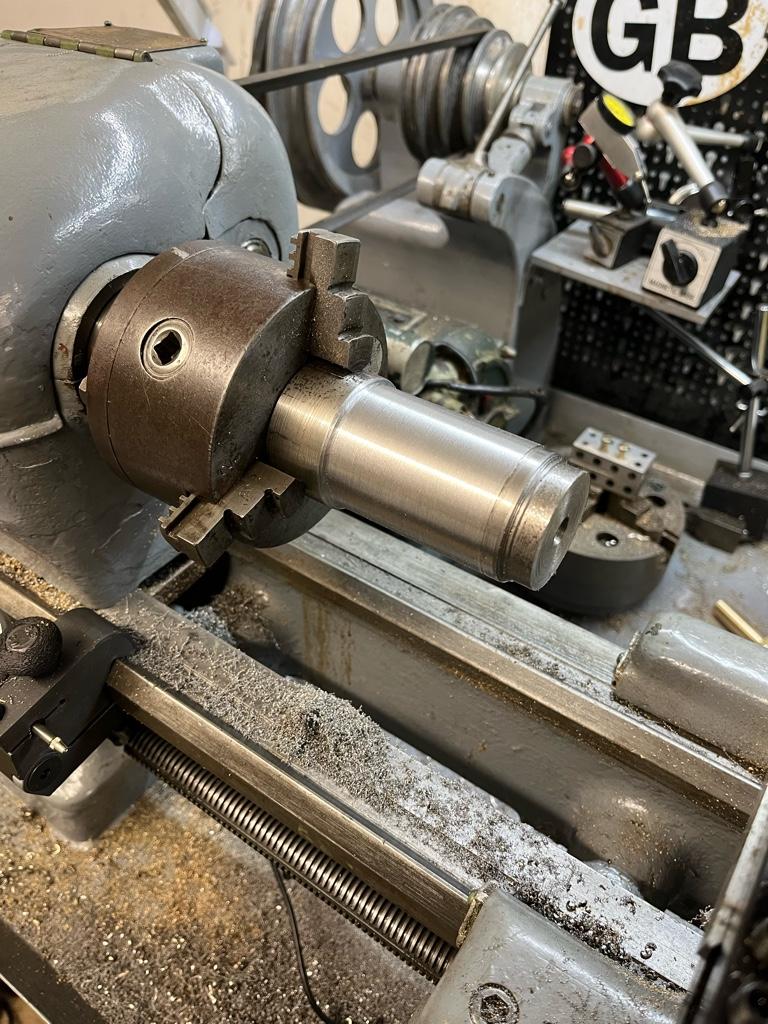

One more problem fixed today:

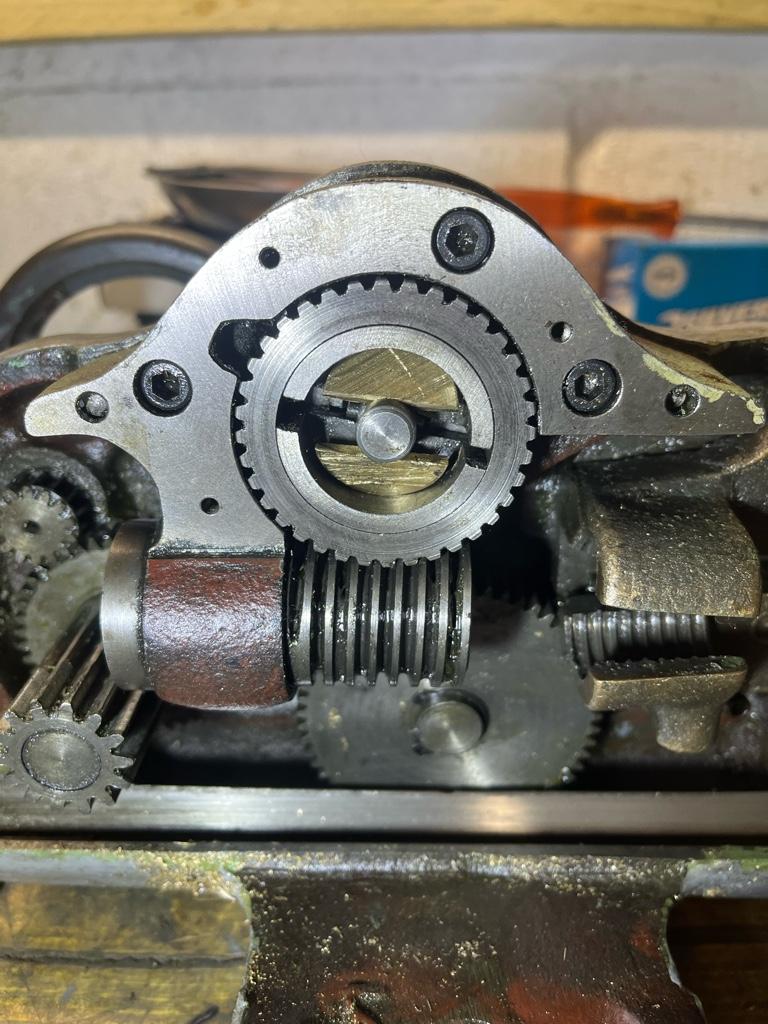

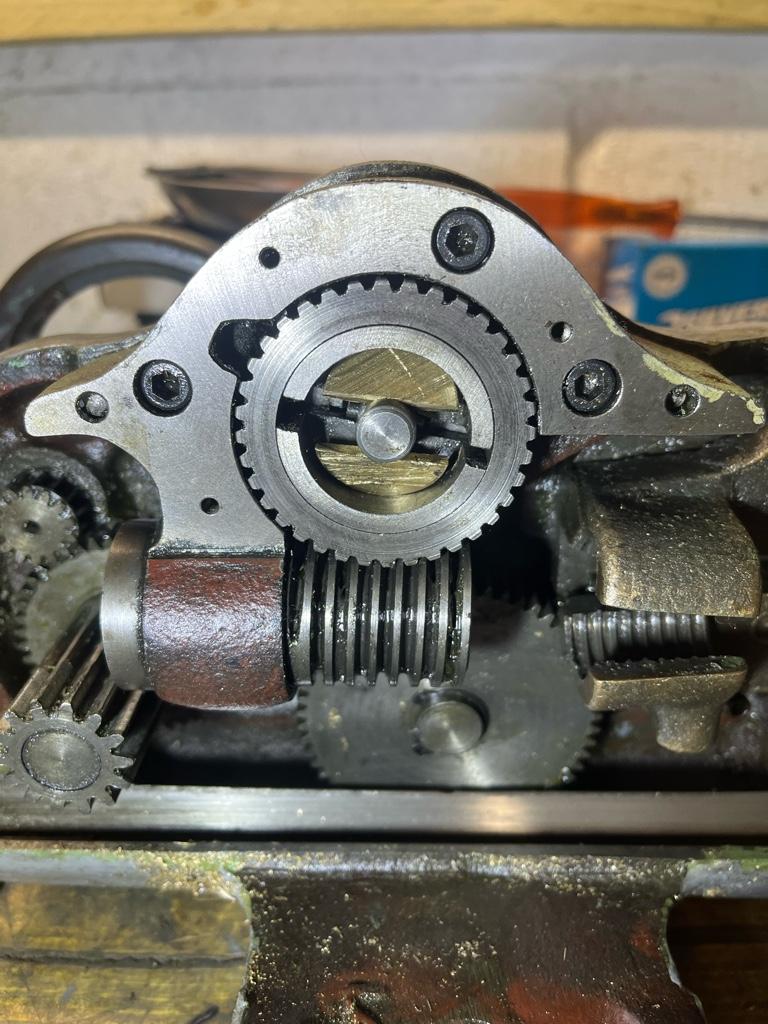

I made the ‘half moon’ (anyone know the real name for these?) parts to push the shoes out to engage the gear and worm drive. I made them out of brass for two reasons 1) that’s what I had to hand in roughly the right size 2) I don’t have any real dimensions for these parts. I couldn’t find that info anywhere. So I figure if they’re the wrong size and in being so cause some wear, I’d rather my parts wear instead of the shoes.

I now have a working power feed!

Sent from my iPhone using Tapatalk

I made the ‘half moon’ (anyone know the real name for these?) parts to push the shoes out to engage the gear and worm drive. I made them out of brass for two reasons 1) that’s what I had to hand in roughly the right size 2) I don’t have any real dimensions for these parts. I couldn’t find that info anywhere. So I figure if they’re the wrong size and in being so cause some wear, I’d rather my parts wear instead of the shoes.

I now have a working power feed!

Sent from my iPhone using Tapatalk

Last edited: