- Joined

- Jul 6, 2022

- Messages

- 498

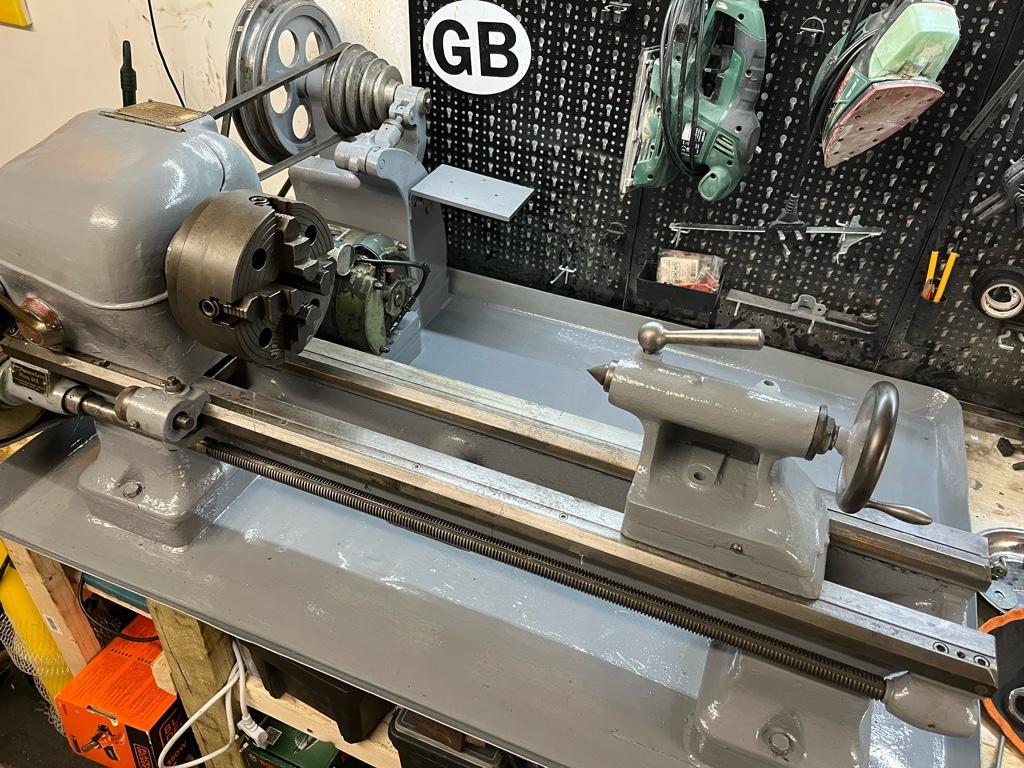

I decided to get the lathe back together albeit not completely painted. Getting it back together and up and running (with a quick bodge to get it kind of fixed to the bench so I could run it up) gave me a bit of a boost in motivation as I could see the end goal. I think when it was completely disassembled all over my workshop it felt too far away from being usable. I think getting it up and running and then taking pieces off one at a time to get painted and finished will be easier for me as I’ll always know that I’m only an hour or so away from being able to use it again.

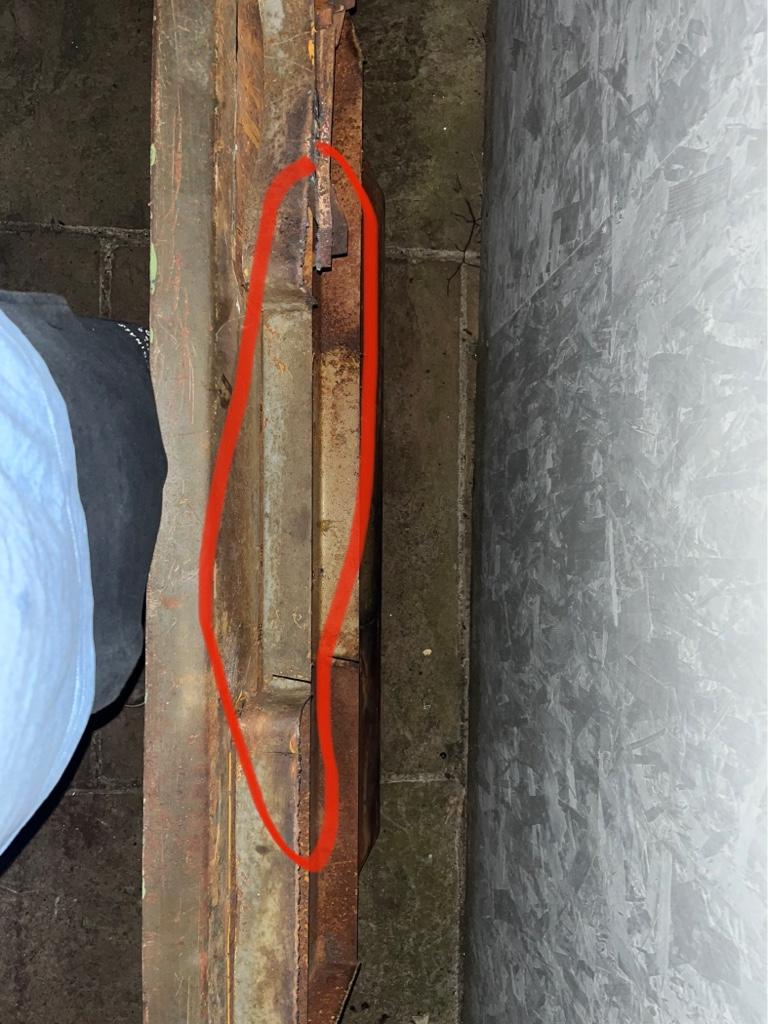

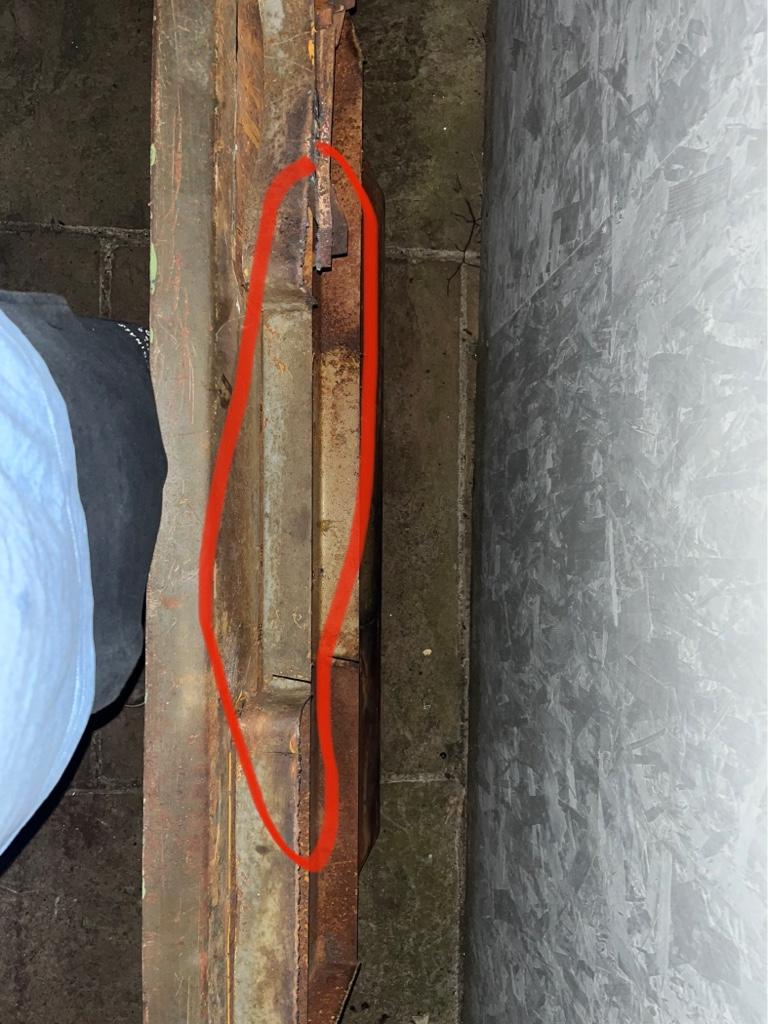

The next job is to get the tray/mount sorted. The lathe was on a cabinet when I bought it, but I didn’t have space for the cabinet and it was in such bad condition that it wouldn’t have been easy to get it back to usable condition. The seller plasma cut the top off and left the first 20cm or so of the base. I need to cut these off to get it flat so it can go on my bench

I’ve taken an angle drinker around it all and none of the edges are now attached. The issue seems to be that the base/legs are attached to a plate that runs flat against the tray (does that make sense?) and getting that off has stumped me

So I’ve got to get the two flat plates that seem to be welded together apart.

I don’t think I’ve explained that very well…. I’ll try again in the morning

Sent from my iPhone using Tapatalk

The next job is to get the tray/mount sorted. The lathe was on a cabinet when I bought it, but I didn’t have space for the cabinet and it was in such bad condition that it wouldn’t have been easy to get it back to usable condition. The seller plasma cut the top off and left the first 20cm or so of the base. I need to cut these off to get it flat so it can go on my bench

I’ve taken an angle drinker around it all and none of the edges are now attached. The issue seems to be that the base/legs are attached to a plate that runs flat against the tray (does that make sense?) and getting that off has stumped me

So I’ve got to get the two flat plates that seem to be welded together apart.

I don’t think I’ve explained that very well…. I’ll try again in the morning

Sent from my iPhone using Tapatalk