- Joined

- Jan 28, 2011

- Messages

- 3,480

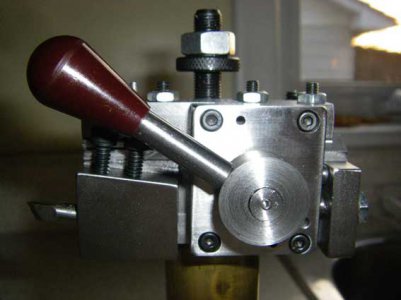

I purchased the Hemingway Tools kit for the Retracting Tool Holder. What you receive are excellent drawings plus the article originally done by the designer G. Thomas, and all the blank steel components as well as the screws, drill blanks for pins etc. Naturally the screws are British thread, not Imperial nor Metric. Since I do not have the taps to thread for these, I replaced them with regular 6x32, 8x32, and 10x24 hardware. I used a knob and handle shaft that I had on hand, instead of cutting a steel ball for the knob.

Total time to finish the build was about 10 hrs. As I did the milling on a light mill I had to take more time than if I had used the BP at work. I have included some pics of the completed holder, before I do the metal treatment to complete the job. I set it up to be used in a Phase II/Aloris clone holder. There is enough meat to cut a vertical dovetail to fit the tool post directly, I would do that if I did this again.

Next week I will beadblast the outer surfaces and do a Phosphate coating to protect the metal.

Total time to finish the build was about 10 hrs. As I did the milling on a light mill I had to take more time than if I had used the BP at work. I have included some pics of the completed holder, before I do the metal treatment to complete the job. I set it up to be used in a Phase II/Aloris clone holder. There is enough meat to cut a vertical dovetail to fit the tool post directly, I would do that if I did this again.

Next week I will beadblast the outer surfaces and do a Phosphate coating to protect the metal.

Last edited by a moderator: