- Joined

- Aug 8, 2019

- Messages

- 19

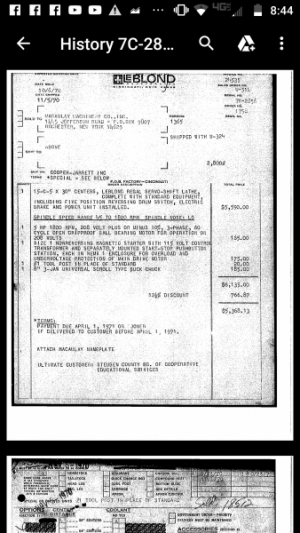

Hey guys, new member here, trying to make this breif, as I have a long winded nature. I am a once before full-time machinist, returning to the field , this time on my own time/dime, in my own hobby shop. Iv purchased several pieces of equipment recently, but the most recent being a 1970 model year Leblond Regal Servo Shift 15x30. Leblond , being super helpful, sent over the original purchasing/build documents. This is a one owner machine, purchased by a trade school, then purchased by myself. Further inspection has gone rather well, so far no mechanical issues within the headstock, but yet to be powered

This lathe uses a 208v 3ph Delco motor, 60HZ. In leblonds documents, they state 208v plus or minus 10%. Iv recently powered my Microcut 1050 manual mill using a VFD for the first time, but this lathe has a more complex design and unsure if a VFD can be used, or is a rotary phase converter is a better option

Can 220v 3ph be used to power the motor?

Has anyone used a VFD for phase conversion on a servo shift lathe?

Iv found a used rotary phase converter locally, 1ph to 3ph, but is a 7.5hp model. Can a 7.5hp model be used for a 5hp model?

This lathe uses a 208v 3ph Delco motor, 60HZ. In leblonds documents, they state 208v plus or minus 10%. Iv recently powered my Microcut 1050 manual mill using a VFD for the first time, but this lathe has a more complex design and unsure if a VFD can be used, or is a rotary phase converter is a better option

Can 220v 3ph be used to power the motor?

Has anyone used a VFD for phase conversion on a servo shift lathe?

Iv found a used rotary phase converter locally, 1ph to 3ph, but is a 7.5hp model. Can a 7.5hp model be used for a 5hp model?