-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RF-30 Clone Head Alignment Guide

- Thread starter Gravydog

- Start date

- Joined

- Jan 1, 2014

- Messages

- 233

Rob,-

Seem there are lots of variations on this style of bench mill. Thanks for the pictures.

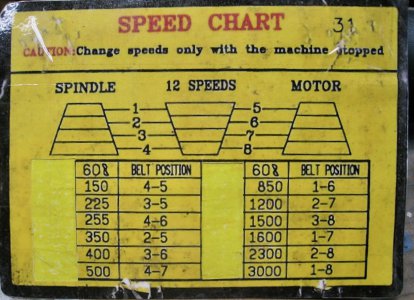

Here is my setup and the speed chart. The 3000 top end is useful for small drills and end mills.

Got tired of flipping the top cover up so removed it and put a shorty safety guard at the front.

By the way, you mentioned column size in your writeup, checked mine and it is a little over 4.5".

Canuck75

Seem there are lots of variations on this style of bench mill. Thanks for the pictures.

Here is my setup and the speed chart. The 3000 top end is useful for small drills and end mills.

Got tired of flipping the top cover up so removed it and put a shorty safety guard at the front.

By the way, you mentioned column size in your writeup, checked mine and it is a little over 4.5".

Canuck75

Attachments

- Joined

- Apr 23, 2018

- Messages

- 6,520

- Joined

- Apr 23, 2018

- Messages

- 6,520

Double vision

Last edited:

- Joined

- Feb 9, 2017

- Messages

- 5,242

I’ve got the same on my Enco RF 30. If you guys haven’t seen it, check out Gravydog’s mod for quick belt adjust. very slick. I’m probably going to do the min and just put some double nuts or nylock nuts on that pesky column adjusters. Why I didn’t think of that before dunno. I do have to say if I had two of them silly idlers like GD, it would have been more on my mind! One idler is bad enough.Rob,-

Seem there are lots of variations on this style of bench mill. Thanks for the pictures.

Here is my setup and the speed chart. The 3000 top end is useful for small drills and end mills.

Got tired of flipping the top cover up so removed it and put a shorty safety guard at the front.

By the way, you mentioned column size in your writeup, checked mine and it is a little over 4.5".

Canuck75

I have an Enco rf30 also. I hated changing the speed so much that I replaced the motor with a VFD and 3 phase motor. I changed the old belts with link belts. Now a speed change involves turning a knob, no fooling with belt guards, etc.

- Joined

- Apr 23, 2018

- Messages

- 6,520

I've posted this several times. It has fixed all head bolt related issues for me. It's about $23 to buy. The spherical nuts move to ensure tension is even. The double nuts are big, and fit the casting in the head. It fixes slipping, crooked clamping, sagging, and nagging spouses. The bill of materials is below.

| ||||||||||||||||||||

Phone (562) 692-5911 Fax (562) 695-2323 Internet www.mcmaster.com Email la.sales@mcmaster.com If the above link and button do not work, paste this web address into your browser to edit and place this order: https://www.mcmaster.com/order/rcvRtedOrd.aspx?ordid=6011065541874&lnktyp=txt |