-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

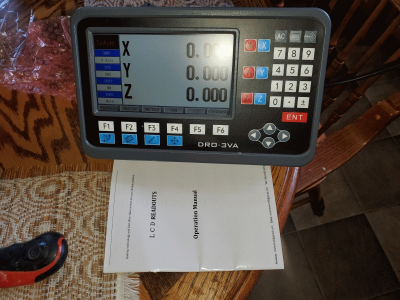

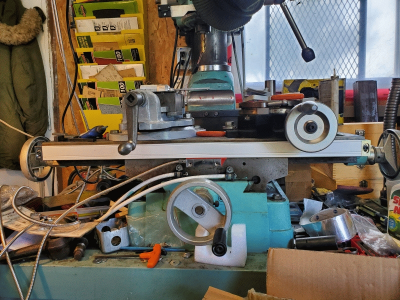

RF30 DRO & Scales Install

- Thread starter Howard E.

- Start date

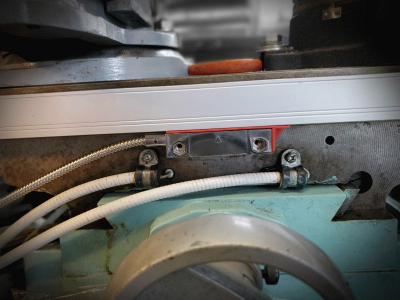

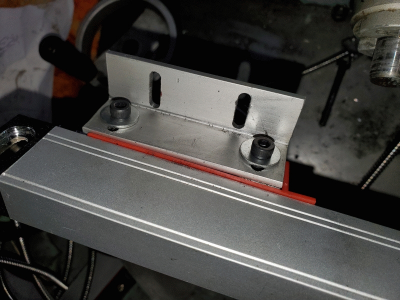

Z Axis-

I decided to mount the scale inside the machine head with the reader tied to the quill.

Here's a look up inside the mill head, I'll use one of those conveniently located holes in the top to secure the upper end of the scale.

The bottom end will be tied by a bracket to the lower part of the mill head casting.

The reader head mounts to a bracket that is tied to the quill collar clamp bolt.

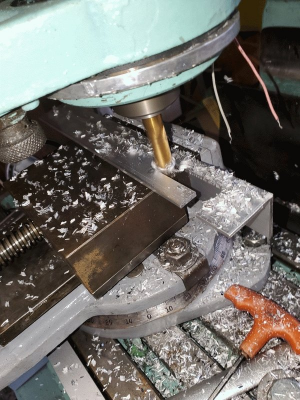

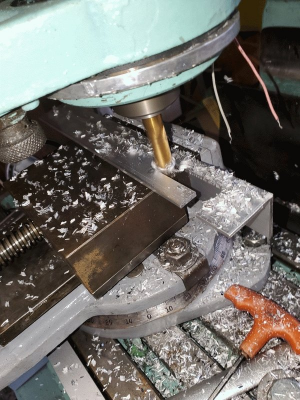

Making the reader bracket-

The quill collar is a pretty rough casting so I needed to clean up the clamp area so the bracket would go on nice & straight.

I decided to mount the scale inside the machine head with the reader tied to the quill.

Here's a look up inside the mill head, I'll use one of those conveniently located holes in the top to secure the upper end of the scale.

The bottom end will be tied by a bracket to the lower part of the mill head casting.

The reader head mounts to a bracket that is tied to the quill collar clamp bolt.

Making the reader bracket-

The quill collar is a pretty rough casting so I needed to clean up the clamp area so the bracket would go on nice & straight.

Last edited:

Issues-

One of the scales died, had to jump through a bunch of hoops to convince the seller what was happening & wait 3 weeks for a replacement.

The replacement scale appeared to have some issues of it's own, plugged into the Y port it worked fine for 3" or so of travel then it started driving the X axis nuts- rapid changes in the reading, like 5 or 6 times normal rate. Sometimes the x would just start counting up at an extreme rate, sometimes moving the x would affect the Y. Tapping a scale would start or stop the craziness. The Z axis worked fine, rock solid.

I suspecteded it was generating some noise on the 5v power rail, after sporadic troubleshooting trying to pin down the source of the problem I eventually ended end up getting a replacement Y scale from a different supplier.

Same thing

Then the X stopped working at all

Had to be the DRO.

So I contacted the seller again explaining the the situation & what I had done to isolate the issue & why I thought the DRO was bad, I also mentioned the two year warranty the advertised on their ebay listings as well as on the back of the manual. After some very creative miss-interpretations of the correspondence they just stopped responding altogether.

Grrrr.

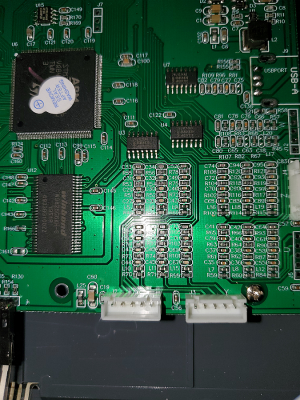

With nothing left to lose I opened up the DRO & started tracing things out-

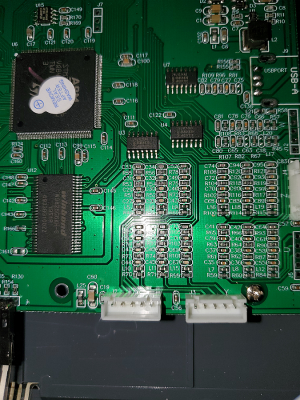

The inputs hit the main board & go through a R-L-C-R-C-R-C-R-C conditioning circuit. There's 3 signal lines per port although the supplied scales only use the A & B lines, I'm guessing the 3rd is for the half rate Z signal even though the manual doesn't show it.

The signal lines run to hex Schmitt triggers- X & Y run to U2, Z to U4. U4 would also handle port "U" for the four channel version.

There's also a U7 that seems to be there for an unused usb port & something (W) that might be a serial interface.

Working through with a scope I could see nice clean square signals all three inputs on X , Y (U3) & Z (U4) but the outputs of U3 were low & had a funny sawtooth component on the low side of the signal waveform which was also showing up on all six lines even with only one scale connected. Z out lines on U4 were clean. I found I could see the sawtooth on U3's pin 7 (ground connection) but not on the ground pad it was soldered to.

???

I hit the pin 7 joint for a sec with the soldering iron & No More Problems

Everything is now working perfectly.

Lesson learned- you buy cheap from china & it's a crap shoot on what happens after that

So with all that I've now found:

Scales from different providers are wired differently- there seems to be no standardization on pin outs for the DB-9 connector. If you mix & match be prepared to do a little re-arraigning with the soldering iron at the connector.

The Z axis scale could have been a little shorter but I ordered everything the next stock size up from what I figured I needed just to give me some options & slop for alignment.

I've found my x lead screw is no wheres near as good as I thought is was, some spots towards the right end are off by 20 thou/"

The Y axis seems to not too bad but there's still some wear.

Z axis is perfect, guess that didn't get used much.

And that's it.

For now ...

One of the scales died, had to jump through a bunch of hoops to convince the seller what was happening & wait 3 weeks for a replacement.

The replacement scale appeared to have some issues of it's own, plugged into the Y port it worked fine for 3" or so of travel then it started driving the X axis nuts- rapid changes in the reading, like 5 or 6 times normal rate. Sometimes the x would just start counting up at an extreme rate, sometimes moving the x would affect the Y. Tapping a scale would start or stop the craziness. The Z axis worked fine, rock solid.

I suspecteded it was generating some noise on the 5v power rail, after sporadic troubleshooting trying to pin down the source of the problem I eventually ended end up getting a replacement Y scale from a different supplier.

Same thing

Then the X stopped working at all

Had to be the DRO.

So I contacted the seller again explaining the the situation & what I had done to isolate the issue & why I thought the DRO was bad, I also mentioned the two year warranty the advertised on their ebay listings as well as on the back of the manual. After some very creative miss-interpretations of the correspondence they just stopped responding altogether.

Grrrr.

With nothing left to lose I opened up the DRO & started tracing things out-

The inputs hit the main board & go through a R-L-C-R-C-R-C-R-C conditioning circuit. There's 3 signal lines per port although the supplied scales only use the A & B lines, I'm guessing the 3rd is for the half rate Z signal even though the manual doesn't show it.

The signal lines run to hex Schmitt triggers- X & Y run to U2, Z to U4. U4 would also handle port "U" for the four channel version.

There's also a U7 that seems to be there for an unused usb port & something (W) that might be a serial interface.

Working through with a scope I could see nice clean square signals all three inputs on X , Y (U3) & Z (U4) but the outputs of U3 were low & had a funny sawtooth component on the low side of the signal waveform which was also showing up on all six lines even with only one scale connected. Z out lines on U4 were clean. I found I could see the sawtooth on U3's pin 7 (ground connection) but not on the ground pad it was soldered to.

???

I hit the pin 7 joint for a sec with the soldering iron & No More Problems

Everything is now working perfectly.

Lesson learned- you buy cheap from china & it's a crap shoot on what happens after that

So with all that I've now found:

Scales from different providers are wired differently- there seems to be no standardization on pin outs for the DB-9 connector. If you mix & match be prepared to do a little re-arraigning with the soldering iron at the connector.

The Z axis scale could have been a little shorter but I ordered everything the next stock size up from what I figured I needed just to give me some options & slop for alignment.

I've found my x lead screw is no wheres near as good as I thought is was, some spots towards the right end are off by 20 thou/"

The Y axis seems to not too bad but there's still some wear.

Z axis is perfect, guess that didn't get used much.

And that's it.

For now ...

Last edited:

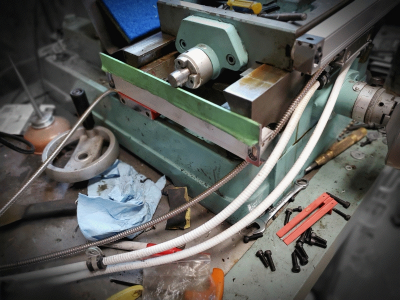

Are those white lines for oil?

No, heater & thermocouple sensor to keep the machine warm for rust prevention.

- Joined

- Oct 16, 2019

- Messages

- 6,570

Fantastic idea!No, heater & thermocouple sensor to keep the machine warm for rust prevention.

Are those white lines for oil?

No, heater & thermocouple sensor to keep the machine warm

Fantastic idea!

Thanks, also a set in the head & the column but since pouring a concrete slab & insulating the shop not really needed anymore so I've now removed them- with the scales added it was just too many wires running around.

Last edited: