- Joined

- Oct 17, 2012

- Messages

- 126

Hey guys,

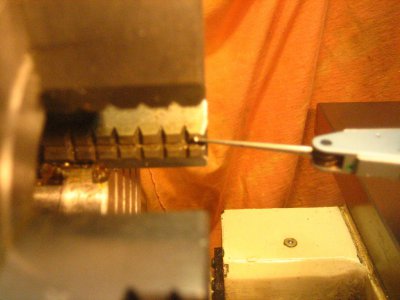

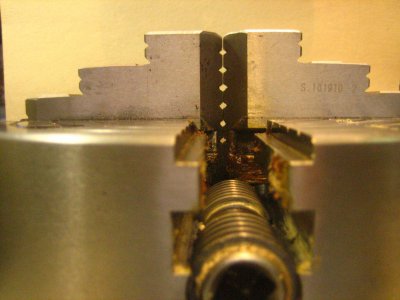

I've got a Rohm 4 jaw which was lotsa $, which I bought due to inability of the bundled 4 jaw to repeat. It has several issues; but the most significant is inability of the jaws to contact workpiece uniformly. Manf says that's normal. I don't know what "normal" is.

My biggest concern is regarding the jaw contact. By the by, all jaws are same. It's as if they are tapered inward toward the front. Very noticeable with alum, and apparent with SS or carbon steel.

What do you think? Need some advice here. Thanks

Mike, Remlap Al

I've got a Rohm 4 jaw which was lotsa $, which I bought due to inability of the bundled 4 jaw to repeat. It has several issues; but the most significant is inability of the jaws to contact workpiece uniformly. Manf says that's normal. I don't know what "normal" is.

My biggest concern is regarding the jaw contact. By the by, all jaws are same. It's as if they are tapered inward toward the front. Very noticeable with alum, and apparent with SS or carbon steel.

What do you think? Need some advice here. Thanks

Mike, Remlap Al