I'm re-assembling my 14x40 & doing some head scratching.

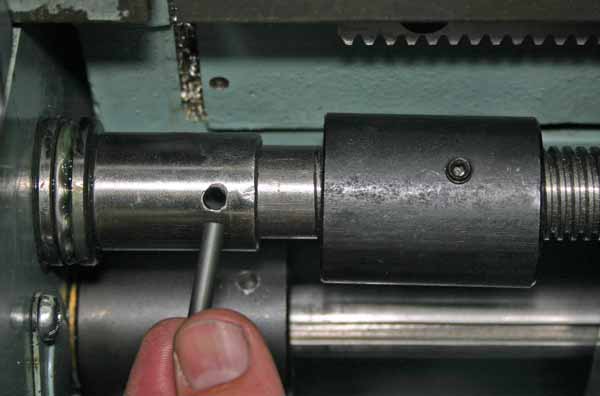

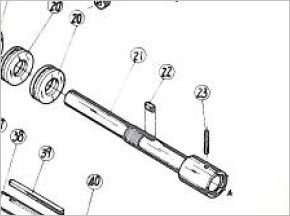

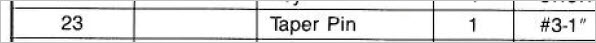

My lead screw had a steel roll pin in it. According the parts manual, its supposed to be a #3 1" taper pin (material unspecified). My picture is showing a stick of black nylon, not using it, just sizing the hole. Anyway I assume this is supposed to be a shear pin designed to fail before taking out the expensive driveline & a steel roll pin probably is too strong? Should I make one out of say brass? The shaft hole isn't the best job, I really don't even think its tapered, or maybe not any more. Once the pin is installed there is a sleeve that goes over & held with a single set screw. I guess its job is to contain the & make for easy replacemnt. Seems fine to me, remember this point for below.

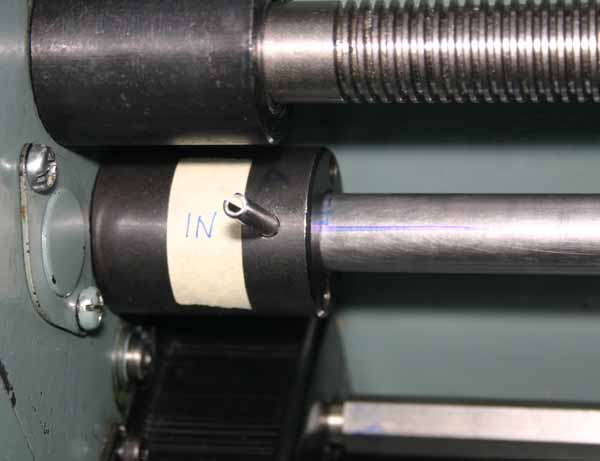

Now the clutch cup. Here the manual calls for a 5mm steel roll pin (which it has). Its not going to shear because of the clutch spring/ball mechanism is designed to disengage long before that if torque builds up. But the roll pin is a PITA to hammer in & out. OK, somewhat aggravated a bit by tight working quarters, odd angle & the usual non-centered (hand drilled?) hole issue typical of these machines. But this got me thinking - why break out the pin punch kit & all that hammering? Why not drop in a nice fitting steel pin & make a similar low profile sleeve like the clutch? Am I off base?

My lead screw had a steel roll pin in it. According the parts manual, its supposed to be a #3 1" taper pin (material unspecified). My picture is showing a stick of black nylon, not using it, just sizing the hole. Anyway I assume this is supposed to be a shear pin designed to fail before taking out the expensive driveline & a steel roll pin probably is too strong? Should I make one out of say brass? The shaft hole isn't the best job, I really don't even think its tapered, or maybe not any more. Once the pin is installed there is a sleeve that goes over & held with a single set screw. I guess its job is to contain the & make for easy replacemnt. Seems fine to me, remember this point for below.

Now the clutch cup. Here the manual calls for a 5mm steel roll pin (which it has). Its not going to shear because of the clutch spring/ball mechanism is designed to disengage long before that if torque builds up. But the roll pin is a PITA to hammer in & out. OK, somewhat aggravated a bit by tight working quarters, odd angle & the usual non-centered (hand drilled?) hole issue typical of these machines. But this got me thinking - why break out the pin punch kit & all that hammering? Why not drop in a nice fitting steel pin & make a similar low profile sleeve like the clutch? Am I off base?