- Joined

- Mar 13, 2017

- Messages

- 55

Hi

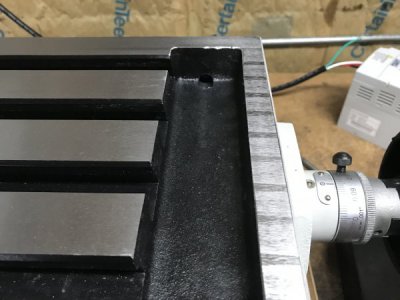

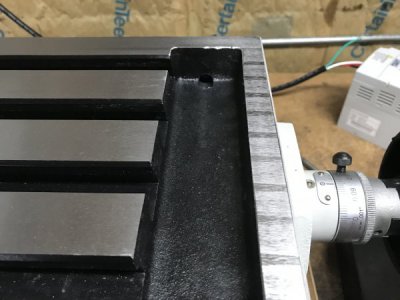

Just received this mill on Monday and not sure what to think. I bought one of these mills about 10 years ago cnced it and then sold it a few years later. I don’t remember the quality being like this, the castings are quite porous, also the ways are very roughly machined. It also seems like the head does not travel down far enough. The table is not machined flat as can be seen by photo. The table x axis is very good but the Y direction has ruts in multiple areas and has a one a half thou difference from end to end.

The machine was loaded with grit and machine dust, a lot more than I remember and way more than other machines I bought in the past few years including Chinese machines. I also noticed that no were on the mill does it say maid in Taiwan. Could this be a fake or clone. I will not mention where I purchased it from yet, but I will say it’s a major company. I also emailed Rongfu for there input, I hope to get a reply.

I cleaned all the screws nuts ways and adjusted gibs. The x axis moves pretty freely but the Y feels stiff even with gib on the loose side and screw turning freely. Could this be the rough machined ways causing this?

I’m still checking out the machine to see what else might be wrong but so far I’m seeing a many issues.

I would appreciate any input on what you guys may think. I would think that the table would have to be ground under warranty at the very least or at worst returned.

Thanks for any help advise.

Just received this mill on Monday and not sure what to think. I bought one of these mills about 10 years ago cnced it and then sold it a few years later. I don’t remember the quality being like this, the castings are quite porous, also the ways are very roughly machined. It also seems like the head does not travel down far enough. The table is not machined flat as can be seen by photo. The table x axis is very good but the Y direction has ruts in multiple areas and has a one a half thou difference from end to end.

The machine was loaded with grit and machine dust, a lot more than I remember and way more than other machines I bought in the past few years including Chinese machines. I also noticed that no were on the mill does it say maid in Taiwan. Could this be a fake or clone. I will not mention where I purchased it from yet, but I will say it’s a major company. I also emailed Rongfu for there input, I hope to get a reply.

I cleaned all the screws nuts ways and adjusted gibs. The x axis moves pretty freely but the Y feels stiff even with gib on the loose side and screw turning freely. Could this be the rough machined ways causing this?

I’m still checking out the machine to see what else might be wrong but so far I’m seeing a many issues.

I would appreciate any input on what you guys may think. I would think that the table would have to be ground under warranty at the very least or at worst returned.

Thanks for any help advise.

Last edited: